Developing your preventive control plan

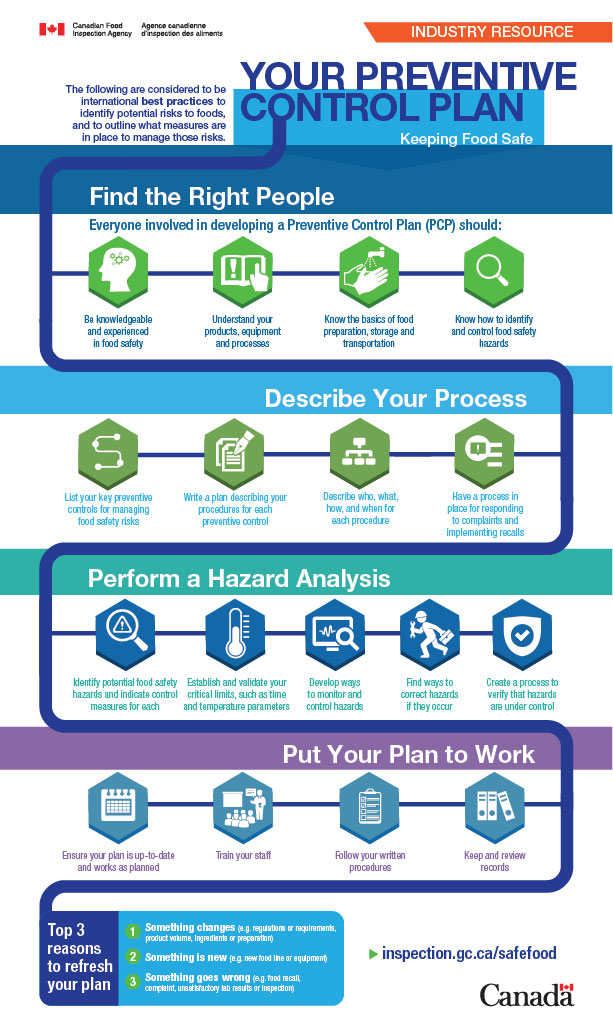

Description of infographic: How to Keep Food Safe: Your Written Preventive Control Plan

Keeping food safe

The following are considered to be international best practices to identify potential risks to foods, and to outline what measures are in place to manage those risks.

Find the Right People:

Everyone involved in developing a Preventive Control Plan (PCP) should:

- Be knowledgeable and experienced in food safety

- Understand your products, equipment and processes

- Know the basics of food preparation, storage and transportation

- Know how to identify and control food safety hazards

Describe Your Process:

- List your key preventive controls for managing food safety risks

- Write a plan describing your procedures for each preventive control

- Describe who, what, how, and when

- Have a process in place for responding to complaints and implementing recalls

Perform a Hazard Analysis:

- Identify potential food safety hazards and indicate control measures for each

- Establish and validate your critical limits, such as time and temperature parameters

- Develop ways to monitor and control hazards

- Find ways to correct hazards if they occur

- Create a process to verify that hazards are under control

Put Your Plan to Work:

- Ensure your plan is up-to-date and works as planned

- Train your staff

- Follow your written procedures

- Keep and review records

Top 3 Reasons to Refresh Your Plan:

- Something changes

(e.g. regulations or requirements, product volume, ingredients or preparation) - Something is new

(e.g. new food line or equipment) - Something goes wrong

(e.g. food recall, complaint, unsatisfactory lab results or inspection)

- Date modified: