PI-009: Seed Potato Tuber Inspection

This page is part of the Guidance Document Repository (GDR).

Looking for related documents?

Search for related documents in the Guidance Document Repository

Table of Contents

- Inspection Procedure

- Appendix 1: Standards for Tubers – Seeds Regulations Part II

- Appendix 2

- Appendix 3: Soft Rot or Wet Breakdown

- Appendix 4: Dry Rot

- Appendix 5: Scab

- Appendix 6

- Appendix 7: Stem end discolouration

- Appendix 8: Malformed and Damage

- Appendix 9

- Appendix 10: Pressure Bruises

- Appendix 11: Oversize and Undersize

- Appendix 12: Defects not Scorable

- Appendix 13: Bacterial Ring Rot

- Appendix 14: Seed Potato Tuber Inspection Report

- Appendix 15: Seed Potato Certification Tags

- Appendix 16: Record of Bulk Movement

- Appendix 17: Photo Credits

Inspection Procedure

4rd Revision

Table of Contents

- Contact

- Review

- Endorsement

- Amendment Record

- Distribution

- Introduction

- Scope

- 1.0 References

- 2.0 Definitions, Abbreviations and Acronyms

- 3.0 Regulatory Tolerance for Seed Potato Tubers

- 4.0 Tuber Inspection Procedures

- 5.0 Packaging and Repackaging Requirements

- 6.0 Requesting a Reinspection of a Shipment

- 7.0 Documents Used in the Seed Potato Certification Program

Contact

The Contact for the review of this document will be the National Manager of the Potato Section, Canadian Food Inspection Agency (CFIA).

Review

The inspection procedure – seed potato tuber shall be reviewed every 3 years, or as required by the Potato Section. The next review date is August, 2017.

Endorsement

Approved by:

![]()

Project Coordinator, Quality System Document Committee

![]()

(date)

![]()

Chief Plant Health Officer

![]()

(date)

Amendment Record

Amendments to this document will be given consecutive numbers. Amendments to this document will be posted on the CFIA Intranet. With hardcopy documents, insert all amendments, remove obsolete pages and ensure the record below is completed.

| Number of amendment: | Amended by: | Date of submission for approval: | Summary of amendment and number of amended section(s): |

|---|---|---|---|

| 4 | Peter Volney | Feb, 2015 |

|

Distribution

The most up to date version of this document will be maintained on the CFIA external website and distributed to participants in the SPTQMP. In addition, the signed original will be maintained in the Directors office and the master electronic copy will be kept in RDIMS.

Introduction

Once a seed potato crop has been entered into the Canadian Seed Potato Certification Program it is inspected to determine regulatory compliance with the standards outlined in the Seeds Regulations Part II, under the authority of the Seeds Act. Inspection is comprised of both field inspection of the growing crop and tuber inspection of graded seed potatoes. This Inspection Procedure (PI) covers tuber inspections and has been developed to provide guidance to growers and designated representatives participating in the Seed Potato Tuber Quality Management Program (SPTQMP) as well as CFIA inspectors conducting SPTQMP audit.

Inspectors must consult chapter 8 & 9 of the Seed Potato Inspection Manual (PI-005) for inspections conducted by the CFIA on shipments that are not eligible to be shipped under the SPTQMP.

Packagers must not be involved in the packaging of table or processing potatoes produced by a non-seed grower unless all the equipment used in transporting, handling and packaging the potatoes has been cleaned and disinfected under the supervision of a CFIA inspector. The CFIA inspector witnessing the cleaning and disinfection must issue a Disinfection Report (CFIA/ACIA 2415) before seed potatoes are received by the packing facility.

If a facility wishes to pack seed potatoes and pack non-seed potatoes at the same time, there must be proper segregation at all times between the seed and non-seed potatoes and the measures used to segregate the potatoes must be approved by the CFIA. All equipment used in transporting, handling and packaging the potatoes must be segregated and must be cleaned and disinfected under the supervision of a CFIA inspector prior to its use for seed potatoes. If proper segregation is not maintained between seed and non-seed potatoes at all times during the process the seed lots handled by the facility may lose their certification as seed.

An inspector must issue a Certification of Authorization (CFIA\ACIA 4378) for domestic shipments of non-registered varieties sold in bags. The producer is responsible for labelling the bags or containers of the non-registered variety; the minimum requirements for these labels are that they list grower or farm unit name, variety, class and certification number.

Scope

This procedure is intended to provide guidance in the inspection of graded seed potato tubers to determine if the seed potato tubers are within the tolerances for size, defects and varietal mixtures as per the Seeds Regulations Part II. It explains the process for identifying, scoring and recording defects, such that the efficiency of the grading operation may be evaluated, allowing the inspector or the participant in the SPTQMP to ultimately determine product acceptability. Other topics covered include packaging, repackaging requirements and documents used in the seed potato certification program.

1.0 References

Potato Field Guide, Insects, Diseases and Defects, Publication 823, Eugenia Banks, 2004, Ministry of Agriculture and Food, Queens Printer for Ontario, Toronto, Ontario.

Seeds Act

Seeds Regulations Part II - Seed Potatoes

PI-005 – Seed Potato Inspection Manual

D-06-04 – Seed Potato Tuber Quality Management Program (SPTQMP)

2.0 Definitions, Abbreviations and Acronyms

Definitions for terms can be found in the Plant Health Glossary of Terms.

3.0 Regulatory Tolerances for Seed Potato Tubers

Appendix 1 lists tolerances for size, defects and varietal mixtures as stipulated in the Section 48 of the Seeds Regulations Part II. All classes of seed potatoes, with the exception of Nuclear Stock class, must be graded to meet the regulatory requirements in Section 48 of the Seeds Regulations Part II. In the case of potato eyes and cut-seed pieces, tubers must meet the grade tolerance prior to cutting. Depending on the nature of the defect, there may be an increased tolerance at the destination over the shipping point. Defects are generally classed as either permanent or conditional defects as explained in section 3.1.

There may be special circumstances where there is an overall shortage of a specific variety or class of seed potatoes and a lot of such a variety or class of seed potatoes does not meet the standards set out in the Seeds Regulations Part II, due to the existence of a single mechanical or physiological defect that cannot be graded easily to the standard without significant loss. In this situation potatoes may be inspected under the SPTQMP, however, the seed potatoes can only be sold within Canada based on a purchaser's agreement and may only move if the CFIA issues a Special Permission for Sale of Seed Potatoes Not Eligible for Official Tags (CFIA/ACIA1278) to the grower. Growers must contact their local office to request issuance of this type of permit under these circumstances.

This permit is only for a single mechanical or physiological defect and cannot be used in conjunction with a shipment of seed potatoes that are over tolerance for any disease caused by a pathogen, e.g. scab, Rhizoctonia, silver scurf, black dot, dry rot, wet rot, etc. In addition, growers must comply with regulatory requirements for Clavibacter michiganensis subsp. sepedonicus, the bacterial pathogen that causes bacterial ring rot (BRR), testing as per Seeds Regulations Part II and directive D-97-12 Seed potato certification program – Bacterial ring rot testing program for field grown seed potatoes.

3.1 Defects

Permanent defects do not progress over time; they are consistent from shipping point to destination. Examples of permanent defects include, but are not limited to: insect injury, grass root injury, growth cracks, hollow heart, mechanical damage (e.g. digger cuts), Rhizoctonia, scab, russetting, skin spot, and sunburn.

Condition defects may progress during transit and reflect the perishable nature of seed potatoes. At shipping point, these defects may not be present or may not be evident, but as the potatoes are handled during shipment, or over time, they may be subjected to conditions which allow symptom expression in excess of permitted tolerances. At destination, some of these defects are provided with increased tolerances to allow for the potential of disease development in transit. Examples of condition defects include: blackleg, blight, air cracks, bruises, soft and dry rot, external discolouration, internal discolouration, freezing and chilling injuries, greening, silver scurf, skin cracks, spraingFootnote 1, and sprouts.

Quarantine pests and regulated non-quarantine pests: A quarantine pest is a pest of potential economic importance to the area endangered thereby and not yet present there, or present but not widely distributed and being officially controlled (International Plant Protection Convention – International Standard for Phytosanitary Measures – (ISPM) No. 5). Examples of quarantine pests of potato in Canada include the causal agents for Potato Wart, Brown Rot and the Golden Nematode. There may be pests of economic importance which are regulated, but not on the quarantine pest list. Examples of regulated non-quarantine potato pests for Canada are the causal agents for Bacterial Ring Rot (BRR) and Potato Spindle Tuber Viroid; these agents have a zero tolerance in the Canadian Seed Potato Certification System, Rhizoctonia, Scab, Wet rot Dry Rot, etc. which have specified tolerances. See appendix 1 Standards for Tubers – Seeds Regulations Part II.

3.2 Varietal Purity

Seed potato tubers in a certified lot are required to be true to variety, with an increased tolerance for foreign tubers (i.e., tubers that are not of the variety being inspected) in seed lots of the lower generation classes. Any tuber of a variety other than that declared as the lot variety, which is found during the inspection of selected samples must be scored as "foreign". The percentage of "foreign" tubers in a lot shall not exceed the percentage permitted for that class as per the Seeds Regulations Part II (refer to Appendix 1 for tolerances).

Note: Varietal characteristics, fluctuations in growing conditions and growing seasons may affect tuber shape (round, oval, long, oblong, elliptical, etc.). Tuber shape may also vary if the potatoes are harvested early. For example, small long types are often round when dug before full maturity.

3.3 Tuber Cleanliness

The Seeds Regulations Part II specifies that no seed tubers shall be washed. This is intended to prevent the establishment of a suitable environment for the development of pathogenic organisms such as bacteria and fungi. If the potatoes have been washed, they are no longer eligible for certification as seed potatoes in Canada. Brushing the tubers is allowed, and when it is performed properly, it does not provide for a suitable environment for disease development.

Tuber cleanliness and freedom from excess soil is a serious issue, both domestically and for many importing countries, since soil can vector many disease pathogens of quarantine significance. Although many countries have strict tolerances for adhering soil, in the Seeds Regulations Part II, there are no set tolerances for soil. However, a grower or his representative should pay special attention to excessive soil presence and, whenever possible, measures should be taken to maintain soil presence below 1%, by weight.

4.0 Tuber Inspection Procedures

Methods for sampling and evaluating tubers are detailed in this section. Detailed information and visual aids to assist in evaluating the tuber diseases, defects and conditions to the required tolerances are found as appendices to this manual.

Presence of soil can interfere with the accuracy of an inspection. Therefore, it is necessary for selected tubers to be sufficiently clean to allow for a visual inspection to be performed. An accurate assessment of a graded shipment cannot be made during an inspection until excess soil is removed from the tubers.

In the case of shipments bound for other international destinations, country-specific tolerances for the presence of soil may apply. It falls under the responsibility of CFIA staff to assess the compliance of a seed potato shipment against the importing countries' requirements.

4.1 Inspection Frequency and Sampling Rates

Tuber samples must be collected so that they are representative of the entire volume being sampled. All shipments under the SPTQMP shall be inspected at the rate outlined in the Appendix 2A. For a shipment to qualify for the reduced sampling rate (0.1% by weight or 250 Tubers), a commercial sized shipment from the same lot must have been inspected and have met the tuber standard within the last 30 days. If no other shipment from the lot has been inspected and met the tuber standard within the last 30 days the sampling rate is 0.5% by weight or 1000 tubers. Any shipment of one MT or greater can be considered a commercial sized shipment.

Tuber inspections not eligible under the SPTQMP must be inspected by the CFIA as per chapter 8 of the Seed Potato Inspection Manual (PI-005) and this document.

The grower or designated representative must choose a method for determining how large a sample to gather, either the percentage by weight or tuber count. A sampling strategy ensures a representative sample is obtained and reflects the total graded shipment. The ideal sample should be randomly selected, accurate, repeatable, and must be randomly drawn from across the entire volume being sampled. The method for drawing the sample will differ between facilities depending on operational practices.

The person taking the sample should take the total sample as a series of sub-samples from a minimum of five points across the total volume being sampled. If a sub-sample container (e.g. a 5 gallon plastic bucket or a wire basket) is being used, once the container has been filled, the contents should be counted or weighed to determine the number of sub-samples needed to equal the total sample required.

Example; If the sub-sample container holds 50 tubers, a total of 20 sub-samples would be required for a 1000 tuber total sample. Weigh the tubers in several of the 50 tuber sub-samples to determine an average kg/sub-sample in order to calculate percentages of oversize and undersized.

While counting tubers to obtain the required sample size as per Seed Potato Tuber Quality Management Program D-06-04, one can evaluate and set aside diseased and defective tubers as detailed in section 4.2.

4.2 Evaluating and Scoring Tuber Samples

In preparation for inspection, assemble any required inspection materials i.e. knives, tuber sizers with square openings, scales, gloves, disinfectant, hand sprayers, etc. Inspection requires detailed examination of a sample of tubers and should be done on a hand rack or grading table in an area with adequate lighting for the evaluation process. Adequate lighting for visual inspection is generally quantified as a minimum of 540 lux. In order to evaluate the adequacy of the lighting, consider that 540 lux is the midrange of acceptable lighting for an office environment, and that under which one can comfortably read finely printed text. 540 lux is the equivalent to the light produced by 3 clear 100 watt incandescent light bulbs spaced 50 cm apart and placed 1 meter above the grading surface or two 48 inch 40 watt fluorescent bulbs in a standard fixture with a reflector placed horizontally 1 meter above the grading surface.

Assess the lot for compliance with Section 48 of the Seeds Regulations, Part II (see Appendix 1). From here on in Section 48 of the Seeds Regulations, Part II will be referred to as the tuber standard. The flow chart in Appendix 2B details the various steps involved in the inspection process and should be referred to in conjunction with this section.

- First appearances can be a determining factor in the inspection process i.e. damp and dirty tubers may require more time to inspect. Scan the entire sample for obvious potential problems i.e. severe scab, rhizoctonia, soft rots, oversized or undersized tubers etc.

- Using the evaluation guide (Appendix 11) and sizers with square openings determine the percentage by weight of the oversized and undersized tubers, and enter the value in the Seed Potato Tuber Inspection Report. After the tubers have been assessed for size the tuber sample/ subsample should be returned to the sample used to asses tuber defects.

- While counting tubers during the sampling process, set aside any tubers which appear to have defects. Appendices to this manual may be used to aid in assessing tuber defects to be scored on the Seed Potato Tuber Inspection Report.

- Observation of any non-scoreable defects which may affect the quality of the tubers should be noted under the Comments section of the Seed Potato Tuber Inspection Report. This will assist in preventing additional problems in the future (i.e. stones, excessive dirt, etc.).

- Some tubers of this sample must be cut to establish the presence or absence of internal discolouration. Tuber cutting and sampling for internal defects is detailed in section 4.3.

- During visual inspection of tubers, record the sample size, and count for each defect in the Seed Potato Tuber Inspection Report.

- Never score the same tuber twice for defects. A tuber with multiple scoreable defects must always be scored for the defect that has the lowest tolerance in the Seeds Regulations Part II. If the defects have the same tolerance in the Seeds Regulations Part II, the tuber must be scored for the defect that affects the largest surface area of the tuber. Size is not considered a defect and is scored by % weight and therefore separately from the defects which are scored by % count.

Calculate total counts and percentages for each defect and compare with the tuber standard tolerance to determine if the lot meets the tuber standard. If the sample exceeds the tolerance for any of the categories, proceed to either resample a greater sample size, or re-grade the shipment as required. For details on re-sampling, growers or designated representatives should consult Appendix 2A for requirements. Under no circumstances a shipment not meeting the tuber standard tolerance for defects and conditions should be allowed to proceed with tags or a RBM under the SPTQMP.

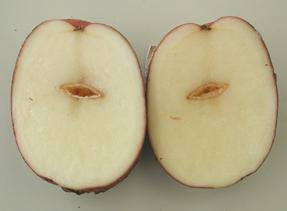

4.3 Sampling and Cutting Procedure for Internal Necrosis

In order to assess tuber samples against the tolerance for internal necrosis a sub-sample of tubers must be cut and examined internally. In drawing the sub-sample as described below, no tuber shall be scored for defects twice. Stem end discolouration is entered in box 21 of the Tuber Inspection Report CFIA ACIA 3076. If internal discolouration and stem-end discolouration are found they are scored under stem end discolouration and damage.

- After scoring the whole sample for all other defects, collect tubers randomly from the un-scored tubers in the sample to create a sub-sample of at least 50 tubers on the initial inspection of a shipment.

- Using the appendices to this manual as a guide for identifying internal defects, every specimen from the sub sample should be cut along the longitudinal axis, drawn through the widest part of the tuber (i.e. from the stem end to the bud end), and examined for internal defects.

- If internal necrosis is found, an additional sample must be drawn and cut to bring the total number of tubers to at least 200. The sample number may be increased, if desired, in order to obtain a larger, more statistically significant sample.

- If internal discolouration or stem end discolouration are observed they are counted out of the total tuber sample and scored under stem end discolouration and damage respectively

- If all the previous inspections conducted on a specific seed lot have been within tolerance for internal necrosis, a minimum of 25 tubers may be taken on subsequent inspections of the same lot to verify the shipment is within the tolerance for internal necrosis.

- Internal necrosis must be scored and this information must be captured in the Seed Potato Tuber Inspection Report. If a tuber does not show signs of internal necrosis and internal discolouration is present, it should be scored under damage. No tuber shall be scored twice for defects.

- Calculate the percentage of tubers that display internal necrosis based on the total number of cut tubers only (25, 50 or 200 tubers) and enter all results in the Seed Potato Tuber Inspection Report In the calculation on the Seed Potato Tuber Inspection Report this number is added to the score for all other defects scored under the Malformed and Damage tolerance.

4.4 Method of Cutting to Determine Depth of Penetration

The scoring of some internal and external tuber defects is dependent on the depth of penetration into the tuber. In some cases when a defect penetrates into the flesh, it is implied that the defect is of a more serious nature and should be rated accordingly. The procedure for determining the depth of penetration is to first make a straight cut at 6 mm deep across the potato from the external surface of the defect, to remove all or most of the surface damage. If the damage is still present in the tuber flesh, then cut another 7 mm off the tuber (a total of 13 mm between the 2 cuts) to determine the full extent of the damage. The depth of penetration is a general indication of the severity of the defect and where it is scored. An example of this is stem end discolouration which is only scored if penetrates the flesh more than 6 mm and less than 13 mm. If the stem end discolouration penetrates less than 6 mm it is not scored for stem end discolouration. If the defect is greater than 13 mm in depth the tuber is scored under internal discolouration.

| < 6 mm | 6 mm to 13 mm | >13 mm |

|---|---|---|

| not scored | stem end discoloration | internal discolouration |

5.0 Packaging and Repackaging Requirements

When potatoes are not shipped in bulk, they are packed in various types of containers such as jute or woven poly sacks, crates, barrels, cartons and totes. Section 54 of the Seeds Regulations Part II specifies packaging and marking requirements for seed potatoes. Seed potatoes may be repackaged for a variety of reasons such as resale for home or garden use; Section 55 of the Seeds Regulations Part II, specifies requirements for the repackaging of seed potatoes.

An inspector must issue a Certification of Authorization for any domestic shipment of non-registered varieties sold in bulk.

5.1 Packages

There are no standard container sizes for seed potatoes. However, shipments usually occur in the following unit sizes:

- 50 lb. (22.7 kg)

- 55 lb. (25.0 kg)

- 75 lb. (34.1 kg)

- 100 lb. (45.4 kg)

- 110 lb. (50.0 kg)

All seed potatoes sold in packages shall be packed in containers that meet all of the following conditions:

- Contain not less than 20 kgFootnote 2,

- Are new,

- Are closed after packaging,

- Bear no markings that refer to non-certified potatoes or are likely to result in the potatoes being mixed with or mistaken for any potatoes other than certified seed potatoes,

- Have a Seed Potato Certification Tag (one of the following: CFIA 1370, 2111, 2113) attached to each container or a Certification of Authorization (CFIA/ACIA 4378) in the case of unregistered varieties.

The CFIA recommends that conveyance (truck bed, trailer, etc.) used to transport the bagged seed potatoes be cleaned and disinfected with a pest control product that is effective in the control of Clavibacter michiganensis subsp. sepedonicus prior to loading.

5.2 Bulk

Records of Bulk Movement (RBM) for Seed Potatoes (CFIA/ACIA 2343) are used to document the movement of seed potato shipments in bulk. The RBMs can be used to document the domestic bulk shipments of registered varieties. When multiple lots are shipped in a single bulk load a grower supplied label meeting the requirements specified below, must be securely affixed to each of the containers, to assist in lot identification for bulk containers such as mini-totes. Except if otherwise stated, a RBM must accompany every shipment.

Note: For domestic shipments moving within the province where the seed lot was produced, a single RBM may be issued for the total volume of a seed lot delivered to a single consignee within a seven day period. The grower or designated representative must provide the consignee within their province with a RBM within seven days of the initial shipment that is covered by the RBM or earlier if requested by the CFIA.

All labels used to identify bulk containers in a shipment must have the following information clearly printed on it;

- Grower or Farm Unit name

- Variety

- Class

- Certification number

Bulk containers that are not new must be washed and disinfected with a disinfectant registered in Canada to be used for the pathogen that causes Bacterial Ring Rot (BRR) (as per the Seeds Regulations Part II, Section 56 (4) (f), "grower's declaration" relating to bulk shipments). Growers who choose to wash and reuse bulk tote bags or containers must submit in writing to the CFIA details of the cleaning and disinfection protocol they intend to follow for approval. The local CFIA staff will review the protocol to determine whether the risk of spread for potato pests is sufficiently mitigated by the proposed protocol.

Prior to loading, the conveyance (truck bed, trailer, etc.) used to transport the seed potatoes in tote bags must be cleaned and disinfected with a pest control product that is effective in the control of Clavibacter michiganensis subsp. sepedonicus.

5.3 Repackaging

Seed potatoes which are packaged under Section 54 of the Seeds Regulations, Part II, (as detailed in section 5.1) may be repackaged. When requested by a packer, the CFIA may issue a Permit Relating to Packing of Seed Potatoes (CFIA/ACIA 1347) which allows for the repackaging of seed potatoes in containers that contain less than 20 kg. Several containers are used for sale for home garden use.

These include:

- 2.2 lb. (1.0 kg)

- 5 lb. (2.27 kg)

- 10 lb. (4.54 kg)

- 20 lb. (9.07 kg)

When a request for a permit has been received, a CFIA inspector will arrange for a time to meet with the packer and conduct a facility inspection. The following elements will be considered:

- That the packer is not involved in the packaging of non-seed potatoes from a non-seed grower or proper segregation between the seed potatoes and the non-seed is maintained. See section 5.1 for more information on segregation of facilities

- That equipment used in repackaging of seed potatoes has been cleaned and disinfected to the satisfaction of the CFIA inspector, prior to use. The CFIA inspector witnessing the cleaning and disinfection must issue a Disinfection Report (CFIA/ACIA 2415) before seed potatoes are received by the repackaging facility.

- The packer will be informed of his/her responsibility to collect and return all documentation associated with the original shipments to the inspector issuing the permit.

- The inspector will provide the packer with a copy of Section 54 and 55 of the Seeds Regulations, Part II as well as information on tuber inspection and grade standards.

If conditions are met to the satisfaction of a CFIA inspector and a Disinfection Report (CFIA/ACIA 2415) has been issued, a Permit Relating to Packing of Seed Potatoes (CFIA/ACIA 1347) will be issued by the CFIA. A Permit Relating to Packing of Seed Potatoes (CFIA/ACIA 1347) is valid for a maximum of one year. Seed potatoes must be repackaged in new containers. Official seed potato tags are not issued by the CFIA for seed potatoes packaged in containers less than 20 kg but the containers must be clearly labelled to show:

- The name and address of the packager

- The class, size (in mm) and variety of the potatoes (non-registered varieties may not be packaged for resale in Canada)

- The seed potato lot certification number.

There is no provision in the Seeds Regulations for the repackaging of Nuclear Stock class seed potatoes.

Seed potatoes which are imported from the US to be repackaged must meet the import requirements as defined in the Plant Protection Act, the Plant Protection Regulations and directive D-98-01: Import Requirements for Seed Potatoes and Other Potato Propagative Material

If seed potatoes are imported from the US for the purpose of repackaging, they must meet the Canadian repackaging requirements, be repackaged in new containers and labelled to show:

- The name and address of the packager

- The variety of the seed potatoes

- The name of the state in which the seed potatoes were grown

- The certification number of the crop.

6.0 Requesting a Reinspection of a Shipment

Any person who receives a shipment of seed potatoes whether they are a seed potato grower or not, may request that CFIA conduct a reinspection of a shipment as per paragraph 60.1(2) of the Seeds Regulations Part II.

The request for re-inspection must be made to the CFIA within two working days of receipt of the shipment in question. Individuals who receive seed potatoes are encouraged to examine each shipment closely upon receipt and contact the local CFIA office within the specified timeframe if it is suspected that the shipment does not comply with the tuber grade sizes, tuber standards or packaging requirements.

7.0 Documents Used in the Seed Potato Certification Program

Section 7.3 is a comprehensive list of forms used in the SPTQMP; some of these forms shall be issued exclusively by the CFIA. Under the Seed Potato Tuber Quality Management Program (SPTQMP), growers will record tuber inspection results on the Seed Potato Tuber Inspection Report (Appendix 14), and may issue both Seed Potato Certification Tags (CFIA/ACIA 1370, 2111, 2113), and Record of Bulk Movement for Seed Potatoes (CFIA/ACIA 2343), as detailed in section 7.1 and 7.2. Growers under the SPTQMP should consult D-06-04 for instructions and information on obtaining required seed potato certification documents from their local CFIA inspection office.

It should be noted that if seed potatoes are sold in bulk for the purpose of packaging and resale, they are not required to be graded when a Permit for Bulk Movement of Seed Potatoes for Packaging and Resale (CFIA/ACIA 4383) has been issued to a grower by the CFIA. Instead, the packager must perform the grading prior to packaging and document issuance before resale or delivery to another farm unit. Before the originating farm unit participating in the SPTQMP may ship un-graded potatoes to another farm unit participating in the SPTQMP the grower from the originating licensed farm unit must have a Permit for Bulk Movement of Seed Potatoes for Packaging and Resale (CFIA/ACIA 4383) and list the other farm unit as a designated representative under the SPTQMP.

7.1 Seed Potato Certification Tags

Seed Potato Certification Tags (CFIA/ACIA 1370, 2111, 2113) (tags) are used to identify shipments in packages greater than 20 kg and they are only used for registered varieties shipped domestically or any variety shipped to internationally. Prior to affixing tags to any container, the grower or the designated representative is responsible for verifying that the tubers in the container meet the tuber standards under the Seeds Regulations Part II. Tags provide a record to the purchaser of the variety and class of seed purchased and are used as proof for re-certification purposes, or other purposes as required under the authority of the Seeds Act or Provincial regulations.

Every certification tag shall contain the following information;

- class, variety and size (in mm)Footnote 3 of the seed potatoes;

- crop certificate number;

- date of printing

- any additional information that is necessary to meet the requirements for the country that will be importing the seed potatoes (if applicable)

Additionally seed tags must contain the declaration below as specified in section 53.5(e) of the Seeds Regulations Part II. This is pre-printed directly on the reverse side of the tags:

"THE GROWER declares that the seed potatoes contained in this shipment are from the crop for which a crop certificate was issued bearing the crop certificate number shown on this tag and that they are graded in accordance with section 48 and subsections 48.1(2) to (10) of the Seeds Regulations.

A request for re-inspection of the seed potato lot may be made to the Canadian Food Inspection Agency within two working days after receipt of the lot.

NOTE: Inspection for the purpose of certification was made either visually or through laboratory testing of samples, or both. Certification does not constitute a warranty, by either the Canadian Food Inspection Agency or the grower, that the seed potatoes meet the applicable standards set out in sections 47.11 to 47.8 of the Seeds Regulations."

Sample seed potato certification tags for Elite (CFIA/ACIA 2113), Foundation (CFIA/ACIA 1370), and Certified (CFIA/ACIA 2111) classes are found in Appendix 12.

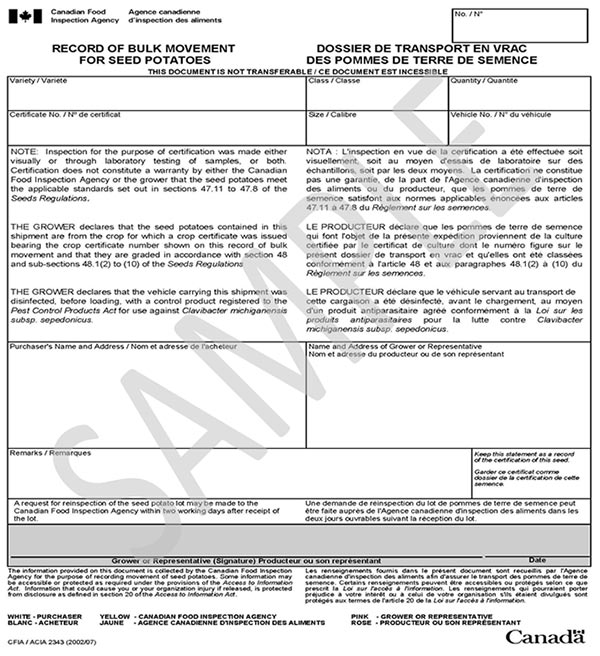

7.2 Record of Bulk Movement for Seed Potatoes (CFIA/ACIA 2343)

A Record of Bulk Movement for Seed Potatoes (CFIA/ACIA 2343) (RBM) is used to identify certified seed potatoes shipped in bulk as well as seed potatoes shipped in mini bulk/tote bags. If multiple lots are shipped in a single bulk load, a grower supplied tag meeting the requirements specified below, must be securely affixed to each of the containers, to assist in lot identification for bulk containers such as mini-totes. For more information on labelling requirements of tote bags, see section 5.1.1. Prior to RBM issuance, it must be verified that seed tubers meet the tuber tolerances under the Seeds Regulations Part II and they are not of an unregistered variety when shipped domestically. The RBM is a controlled document which provides proof of a lot's certification origin, and is used for recertification purposes, or other purposes as required under the authority of the Seeds Act or Provincial regulations.

Every RBM shall contain the following information;

- weight, class, variety, size (in mm)Footnote 4 and quantity of the seed potatoes;

- crop certificate number;

- the name and address of both the consigneeFootnote 5 (purchaser), and grower or representativeFootnote 6

- signature of the grower or representative

- date of signature

- additional information to meet importing country requirements (if applicable)

Before the RBMs are completed they must be kept under the secure control of the grower or designated representative(s) and must not be made available to any party other than the CFIA.

Additionally the RBM must contain the declaration below as specified in section 53.5(e) of the Seeds Regulations Part II. This is pre-printed directly on the RBM certificate.

"THE GROWER declares that the seed potatoes contained in this shipment are from the crop for which a crop certificate was issued bearing the crop certificate number shown on this record of bulk movement and that they are graded in accordance with section 48 and subsections 48.1(2) to (10) of the Seeds Regulations.

THE GROWER declares that the vehicle carrying this shipment was disinfected, before loading, with a control product registered under the Pest Control Products Act for use against Clavibacter michiganensis subsp. sepedonicus.

A request for re-inspection of the seed potato lot may be made to the Canadian Food Inspection Agency within two working days after receipt of the lot.

NOTE: Inspection for the purpose of certification was made either visually or through laboratory testing of samples, or both. Certification does not constitute a warranty, by either the Canadian Food Inspection Agency or the grower, that the seed potatoes meet the applicable standards set out in sections 47.11 to 47.8 of the Seeds Regulations."

A sample Record of Bulk Movement for Seed Potatoes (CFIA/ACIA 2343) is found as Appendix 16.

7.2.1 Transferability of a Record of Bulk Movement for Seed Potatoes

Section 56(5) of the Seeds Regulations Part II states that, "a Record of Bulk Movement is not transferable." This means that if a shipment of potatoes is moving under a RBM the shipment must go to the location stated as the purchaser (consignee). If the shipment covered by the RBM is being transferred to another location other than the stated purchaser and traceability of the shipment has been maintained, the RBM must be returned to the seller and a new RBM must be issued stating the name and address of the new location.

Note: The RBM cannot be withheld by the seller for any reason once movement has been completed for any amount of seed.

7.3 Forms Used by Growers Participating in the SPTQMP

The following is an alphabetical list of forms used by growers participating in the SPTQMP.

Application for a Licence to Use Seed Potato Certification Tags and Record of Bulk Movement for Seed Potatoes (Appendix 1, D-06-04)

This form is used by a grower to apply for the SPTQMP and to request changes to conditions of the grower's licence.

Designated Representatives List- SPTQMP (Appendix 2, D-06-04)

This form is used by growers to designate representatives under the SPTQMP and notify the CFIA that an individual has been identified as a designated representative.

Record of Bulk Movement for Seed Potatoes (CFIA/ACIA 2343)

A certificate issued by the grower, designated representative participating in the SPTQMP or a CFIA inspector authorizing the sale and transport of seed potatoes in bulk. This form is used to permit movement of graded registered varieties within Canada and all varieties for export.

Request for Seed Potato Certification Tags or Record of Bulk Movement for Seed Potatoes (Appendix 4, D-06-04)

This form is used by growers and designated representatives participating in the SPTQMP to request tags or Record of Bulk Movement for Seed Potatoes certificates from the CFIA. The growers and designated representatives may use their own forms to request tags as long as they meet the requirements of the CFIA.

Seed Potato Certification Tags: Elite (CFIA/ACIA 2113), Foundation (CFIA/ACIA 1370), Certified (CFIA/ACIA 2111)

Certificates that are issued by the grower, designated representative participating in the SPTQMP or a CFIA inspector and are attached to containers of seed potatoes greater than 20 kg to identify class, variety and lot.

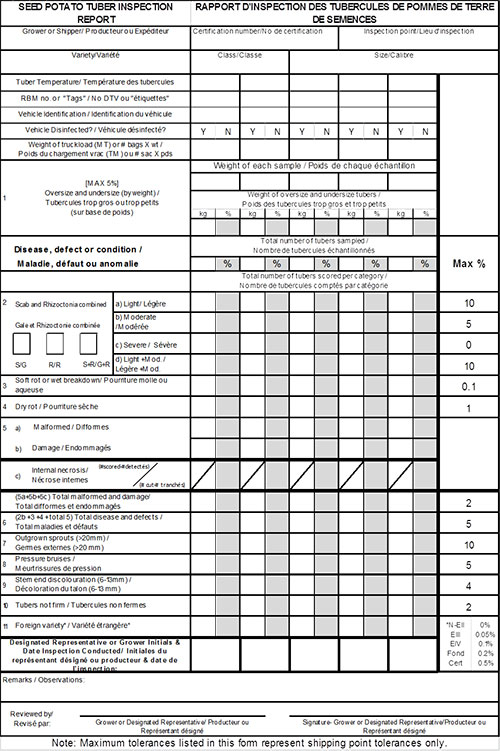

Seed Potato Tuber Inspection Report (CFIA/ACIA 3076 / Appendix 14)

Used with all tuber inspections by CFIA inspectors and growers or designated representatives participating in the SPTQMP to record the tuber conditions of the lot being assessed. The growers and designated representatives may use other forms to record the tuber inspection results as long as they meet the requirements of the CFIA. CFIA inspectors may only use the Seed Potato Tuber Inspection Report CFIA 3076 to record inspection results. Also, additional information and observations such as maps, diagrams, and narrative descriptions should also be noted on the Seed Potato Tuber Inspection Report CFIA 3076 form during harvest/bin inspections and re-inspections.

Shipment Record Log -Record of Bulk Movement for Seed Potatoes: SPTQMP (Appendix 6, D-06-04)

This form is used by growers and designated representatives participating in the SPTQMP to keep track of the issuance of Record of Bulk Movement for Seed Potatoes under a grower's licence. Growers and designated representatives may develop their own shipment record log to record the required information as long as they meet the requirements of the CFIA.

Shipment Record Log- Seed Potato Certification Tags: SPTQMP (Appendix 5, D-06-04)

This form is used by growers and designated representatives participating in the SPTQMP to keep track of the issuance of tags under a grower's licence. Growers and designated representatives may develop their own shipment record log to record the required information as long as they meet the requirements of the CFIA.

7.4 Forms Issued by CFIA inspectors in Relation to the SPTQMP

The following is an alphabetical list of forms used by CFIA inspectors in relation to the SPTQMP.

Audit Report: SPTQMP

This form is used by CFIA inspectors to record the details of audit findings for farms participating in the SPTQMP.

Certification of Authorization (CFIA/ACIA 4378)

This form is issued by a CFIA inspector; it permits the movement, between farm units in Canada, of seed potatoes of a non-registered variety for which a crop certificate has been issued.

Corrective Action Request: SPTQMP

This form is issued by inspectors to document deficiencies in the application of the SPTQMP on a farm unit and to ask a grower to correct the identified deficiency. Growers may use this form to respond to the inspector's request for a corrective action.

Disinfection Report (CFIA/ACIA 2415)

This report is issued by a CFIA inspector to document the disinfection of equipment at a farm or a facility handling seed potatoes.

Growing Crop Certificate (CFIA/ACIA 1318)

This certificate is issued by the CFIA when an inspector certifies a seed potato crop. This certificate specifies the variety, class, area, and the certification number of every lot certified as seed potato on the farm unit. This is a single document to grant certification on all crops meeting the class standard for each applicant.

Licence to Use Seed Potato Certification Tags and Record of Bulk Movement for Seed Potatoes

A licence issued by a CFIA inspector authorizing the use of Seed Potato Certification Tags and Record of Bulk Movement Certificates. The licence also states the conditions that the grower must follow when using Seed Potato Certification Tags and Record of Bulk Movement Certificates.

Notification of a Change in the Status of a Licence to Use Seed Potato Certification Tags and Record of Bulk Movement for Seed Potatoes

This form is issued by a CFIA inspector to notify applicants and participants of changes in their licence status or the denial of a licence application.

Permit for Bulk Movement of Seed Potatoes for Packaging and Resale (CFIA/ACIA 4383)

A permit issued by a CFIA inspector authorizing the movement of seed potatoes that are sold in bulk for the purpose of packaging and resale and are not required to be graded by the grower. The packager must do the grading prior to packaging and resale.

Permit Relating to Packing of Seed Potatoes (CFIA/ACIA 1347)

A permit issued by a CFIA inspector authorizing the packing and repackaging of seed potatoes.

Special Permission for Sale of Seed Potatoes not Eligible for Official Tags (CFIA/ACIA 1278)

A document issued by a CFIA inspector granting permission to a seed potato grower for the sale of seed potatoes of any class having a single defect or damage in excess of established tuber standard. These defects are limited to mechanical and physiological tuber damage. This option should be only used for sales of seed within Canada and for varieties in short supply or other special situations, as determined and approved by the CFIA.

Appendix 1: Standards for Tubers – Seeds Regulations Part II

| Disease or Defect | Tolerance by Count at Shipping Point |

Tolerance by Count at Destination |

|---|---|---|

| Soft rot or wet breakdown | 0.1 % | 0.5 % |

| Dry rot, including late blight | 1.0 % | 1.0 % |

Scab and Rhizoctonia combinedTable Note 7

|

10.0 % |

10.0 % |

| Stem-end discolouration due to top-killing, frost, heat or drought, with penetration from 6 mm to 13 mm | 4.0 % | 4.0 % |

| Malformed and damage | 2.0 % | 3.0 % |

| Total number of diseases and defectsTable Note 8 | 5.0 % | 5.0 % |

Table Notes

- Table Note 7

-

The total of the combined light, and combined moderate Scab and Rhizoctonia categories must not exceed 10%. No severe Scab or Rhizoctonia is allowed.

- Table Note 8

-

The total of combined tolerances for diseases and defects (not including light scab, light Rhizoctonia and stem-end discolouration), shall not exceed 5% of the total number of tubers in the lot.

| Condition | Tolerance by Count |

|---|---|

| Tubers that are not firm | 2.0 % |

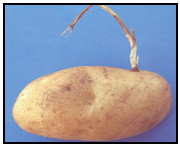

| Outgrown sprouts (exceeding 20 mm) | 10.0 % |

| Pressure bruises | 5.0 % |

| Oversize and undersize | 5.0 % by weight |

| Varietal Mixture | Tolerance by Count |

|---|---|

| Nuclear | 0.0% |

| Pre-Elite | 0.0% |

| Elite I | 0.0% |

| Elite II | 0.0% |

| Elite III | 0.05 % |

| Elite IV | 0.1 % |

| Foundation | 0.2 % |

| Certified | 0.5 % |

Note: Descriptions and tolerances are for reference only; refer to Seeds Regulations Part II for complete information

Appendix 2

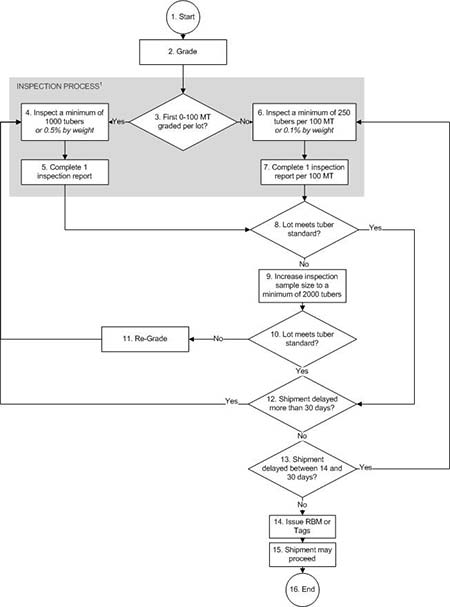

2a: Process for Domestic Seed Potato Shipments: SPTQMP

Click on image for larger view

Description for Flowchart - Process for Domestic Seed Potato Shipments: SPTQMP

This flowchart describes the process that a grower or a designated representative must follow to ship potatoes under the SPTQMP.

Box 1. Start, proceed to Box 2.

Box 2. Grade, proceed to Box 3.

Box 3. First 0-100 MT graded per lot? Yes, proceed to Box 4. No, proceed to Box 6.

Box 4. Inspect a minimum of 1000 tubers or 0.5% by weight, proceed to Box 5.

Box 5. Complete 1 inspection report, proceed Box 8.

Box 6. Inspect a minimum of 250 tubers per 100 MT or 0.1% by weight, proceed to Box 7.

Box 7. Complete 1 inspection report per 100 MT, proceed to Box 8.

Box 8. Lot meets tuber standard? No, proceed to Box 9. Yes, Proceed to Box 12.

Box 9. Increase inspection sample size to a minimum of 2000 tubers, Proceed to Box 10.

Box 10. Lot meets tuber standard? No, proceed to Box 11. Yes, proceed to Box 12.

Box 11. Re-grade, proceed to Box 4.

Box 12. Shipment delayed more than 30 days? Yes, proceed to Box 4. No, proceed to Box 13.

Box 13. Shipment delayed between 14 and 30 days? Yes, proceed to Box 6. No, proceed to Box 14.

Box 14. Issue RBM or Tags, proceed to Box 15.

Box 15. Shipment may proceed, proceed to Box 16.

Box 16. End

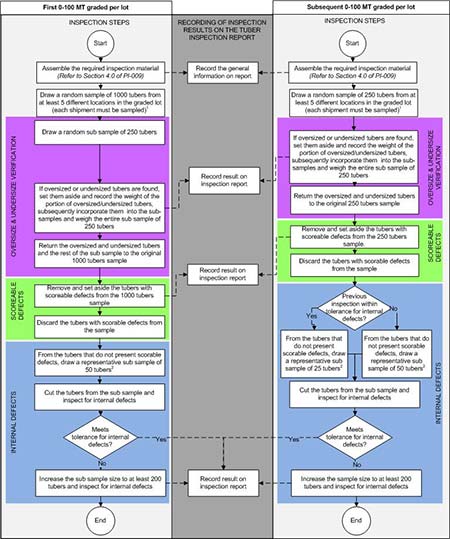

2b: Domestic Seed Potato Inspection Process: SPTQMP

Click on image for larger view

Description for Flowchart - Domestic Seed Potatoes Inspection Process: SPTQMP

This flowchart describes the steps that a grower or a designated representative needs to follow to complete a tuber inspection.

For the first 0-100 MT graded per lot

Start

Assemble the required inspection material (Refer to Section 4.0 of PI-009), Draw a random sample of 1000 tubers from at least 5 different locations in the graded lot (each shipment must be sampled).

Note: The sample must be randomly selected (randomly drawn from across the entire volume being sampled). Record the general information on report.

Oversize & undersize verification

Draw a random sub sample of 250 tubers. If oversized or undersized tubers are found, set them aside and record the weight of the portion of oversized/undersized tubers, subsequently incorporate them into the sub-samples and weigh the entire sub sample of 250 tubers. Record result on inspection report. Return the oversized and undersized tubers and the rest of the sub sample to the original 1000 tubers sample

Scoreable defects

Remove and set aside the tubers with scoreable defects from the 1000 tubers sample. Record result on inspection report. Discard the tubers with scorable defects from the sample.

Internal defects

From the tubers that do not present scorable defects, draw a representative sub sample of 50 tubers.

Note: The evaluation of the internal defects must be done on tubers that do not present scoreable defects (tubers with scoreable defects should be discarded from the main sample before the selection of the sub sample that will be used to assess the internal defects. Cut the tubers from the sub sample and inspect for internal defects. Meets tolerance for internal defects? Yes, Record result on inspection report. No, Increase the sub sample size to at least 200 tubers and inspect for internal defects.

Finish

Subsequent 0-100 MT graded per lot

Start

Assemble the required inspection material (Refer to Section 4.0 of PI-009), Draw a random sample of 250 tubers from at least 5 different locations in the graded lot (each shipment must be sampled).

Note: The sample must be randomly selected (randomly drawn from across the entire volume being sampled).Record the general information on report.

Oversize & undersize verification

If oversized or undersized tubers are found, set them aside and record the weight of the portion of oversized/undersized tubers, subsequently incorporate them into the sub-samples and weigh the entire sub sample of 250 tubers. Record result on inspection report

Return the oversized and undersized tubers to the original 250 tubers sample

Scoreable defects

Remove and set aside the tubers with scoreable defects from the 1000 tubers sample. Record result on inspection report. Discard the tubers with scorable defects from the sample.

Internal defects

Previous

inspection within tolerance for internal defects? Yes, from the tubers that do not present scorable defects, draw a representative sub sample of 25 tubers2. No, from the tubers that do not present scorable defects, draw a representative sub sample of 50 tubers2. Note 2: The evaluation of the internal defects must be done on tubers that do not present scoreable defects (tubers with scoreable defects should be discarded from the main sample before the selection of the sub sample that will be used to assess the internal defects.

Cut the tubers from the sub sample and inspect for internal defects Meets tolerance for internal defects? Yes, Record result on inspection report. No, Increase the sub sample size to at least 200 tubers and inspect for internal defects.

Finish

Appendix 3: Soft Rot or Wet Breakdown

Causal agents:

Soft rot or wet breakdown is the general term used to describe tuber decomposition which may involve one or more fungi and/or bacterial agents. Soft rot may also be induced by mechanical or physical damage to the tuber such as by frost injury (1), freezing and chilling injuries (2) and bruising, and subsequent infection. Freezing injury most often shows a complete break down and watery rot of affected tubers. Tubers which have been exposed to freezing temperatures and allowed to warm up for 1 week to 10 days usually express classic symptoms of soft rot. Pathogenic agents of soft rot may include: Fusarium spp. (3), Blackleg or bacterial soft rot - Pectobacterium carotovorum subsp. carotovorum (4, 5), Early blight - Alternaria solani, Late Blight - Phytophthora infestans, Leak fungus - Pythium ultimum var. ultimum (6), among many others. Certain pathogens may be causative agents of both soft rot and dry rot.

Scoring:

In scoring soft rot or wet breakdown it is not always necessary to identify the specific pathogen affecting the tuber. Images below are not representative of all symptoms which may be encountered; any soft, mushy breakdown, soft leaking specimens or soft and watery tissue must be scored under the tolerance for soft rot or wet breakdown. Refer to Seeds Regulations Part II for tolerances. Quarantine pests may exhibit similar symptoms to soft rot, consult additional resources for information.

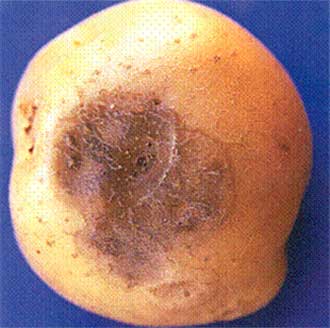

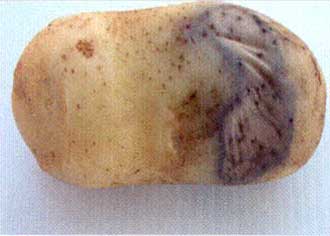

Description for 1

This is an image of a potato with wet spots caused by frost damage. There is a patch of dark brown sunken skin on the potato taking up 20% of its visible surface area which is a result of the frost damage.

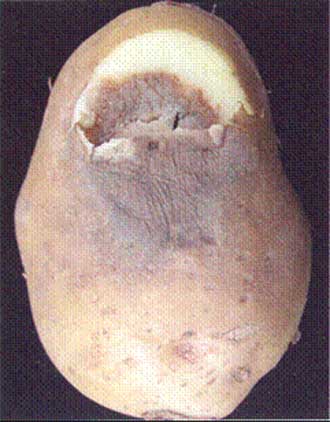

Description for 2

This is an image of a potato containing soft black tissue caused by freezing damage. It is cut in half down the middle so that the inside of the potato is visible. The potato's inside is nearly all black-brown with a concentration around the edges and a white area surrounding the black-brown core of the potato.

Description for 3

This is an image of a brown potato that shows a jelly-like consistency of tuber flesh as a result of a pathogenic agent of soft rot called Fusarium spp. The rot has caused a dark spot on the visible side of the potato to appear taking up approximately 20% of its surface area. A small portion of the potato is cut to show that the jelly-like consistency goes deeper than the surface.

Description for 4

This image of brown potato shows the external tuber soft rot caused by a bacterial soft rot known as Pectobacterium carotovorum subsp. carotovorum. Half of the potato skin is unaffected and the remaining skin has blackened, receding edges. Small yellow spots cover the entire potato acting as its distinguishing feature with small white spots here and there.

Description for 5

This is an internal image of a potato with tuber soft rot caused by a bacterium known as Pectobacterium carotovorum subsp. carotovorum. The potato is cut down the centre to reveal how the greater part of the potat's center has turned into a soft deformed mash outlined by blackened tissue.

Description for 6

This is an image of a yellow potato with watery grey Leak fungus infection known as Pythium ultimum var. ultimum. The infection is present on one third of the visible side of the potato. The infected area is outlined in black and contains black spots over that area of skin which appears to be spreading.

Appendix 4: Dry Rot

Causal agents:

Dry rot is the term used to describe dry decomposition, usually starting in cuts, bruising or other injuries. Dry rot is most often caused by Fusarium spp. (7,8).Other conditions or pathogens may result in dry rot. White knot or Starch spot (9) is a bruising which appears as a hard white lump in the tuber flesh a few millimeters below the skin; this is similar to Black spot except the coloration is lacking. Both White knot and Black spot (10) start out as a bruising injury but may develop into a dry rot in severe cases. Additional pathogens resulting in dry rot include, Late blight - Phytophthora infestans (11), Early blight - Alternaria solani (12), Blackleg - Pectobacterium carotovorum subsp. carotovorum, as well as severe Skin Spot - Polyscytalum pustulans, among others. As well, mechanical and physiological damage which has dried, such as pressure bruising, or dried frost and freezing injuries often result in dry rot. In storage below 4°C, dry rot fungi in small lesions may remain dormant, however upon planting may be quickly attacked by soft rot bacteria which rot the tuber very quickly. Certain pathogens may be causative agents of both dry rot and soft rot.

Scoring:

As in the case of soft rot or wet breakdown, it is not always necessary to identify the specific pathogen affecting the tuber. Dry rot is scored under the dry rot tolerance when it affects the flesh of the potato and penetrates more than 6 mm in depth or is less than 6 mm in depth but covers more than 10% of the surface area. It may be slightly moist but not wet, and thus is not considered a "wet" rot. Refer to Seeds Regulations Part II for tolerances.

Details for Image 7

Fusarium spp. The potato is a light-yellow colour in a horizontal position, with the state of dry decomposition beginning on its left side. The decomposing area takes up 30% of the viewed side of the potato, it is a purple-brown colour which demonstrates bruising, and has a few wrinkles on the bruised area.

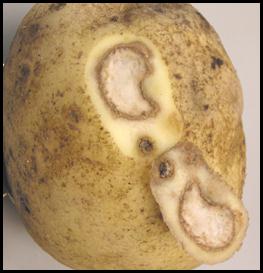

Details for Image 8

This image of a potato is another demonstrating a form of dry rot caused by Fusarium spp. The potato is cut in half so that the inside of the potato is visible. The decomposition begins on the left side of the potato, takes up 75% of the cut surface area, and is a dark-brown colour. The decomposition occurs in one large spot and has a few surrounding smaller spots. Several hollow areas have formed due to decomposition.

Details for Image 9

This is an image of a potato demonstrating dry rot in the form of a white knot or starch spot. This form of decomposition involves bruising which appears as a hard white lump in the tuber flesh a few millimeters below the skin. In this image there is one main spot shown on the potato; a small portion of the skin has been peeled off, but is still attached, demonstrating that the white spot occurs below the potato skin. The spot in this picture is shaped like an upside-down teardrop, with a tiny dark spot showing another area beginning to decompose.

Details for Image 10

This is an image of a potato demonstrating dry rot in the form of a black spot. Black spots are similar to white spots in that they are a hard lump in the tuber flesh a few millimeters below the skin, but in this case they are a dark black/brown colour. In this image only a portion of the skin the size of a nickel has been peeled off to demonstrate this form of decomposition below the skin.

Details for Image 11

This is an image of a potato demonstrating dry rot in the form of a Late Blight – tan to brown granular dry rot. The potato in this image has a light brown skin and has been cut in half. On the half that is exposed, 75% of its cut surface area appears as a dark brown colour, demonstrating its decomposition, leaving the other 25% being its natural cream colour.

Details for Image 12

This is an image of a potato demonstrating dry rot in the form of an Early Blight-shallow infection, dry corky and brown. It is a red-skinned potato with the rot taking up approximately 10% of its surface area. The area with the decomposition appears dry, crusted, and somewhat bumpy. It is a medium and dark-brown colour, and with a crack forming in the middle.

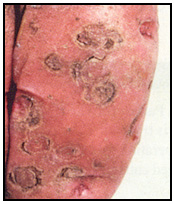

Appendix 5: Scab

5a: Powdery Scab

Causal agents:

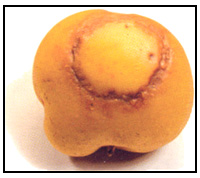

Powdery scab is caused by the fungus Spongospora subterranea, which may survive for many years in the soil as resting spores. The fungus attacks roots, stolons, young shoots and tubers of the developing plant, and may penetrate tubers through lenticels or wounds. It is generally spread by planting infected tubers, moving or spreading contaminated soil or manure. Motile spores of powdery scab can also vectors of Potato Mop Top Virus (PMTV).

Powdery Scab symptoms initially appear on young tubers as purplish-brown sunken lesions, developing into faintly brown raised areas which occur singularly or in patches. Within approximately one week, under ideal conditions these areas enlarge to about 6 mm. When mature, these pustules become yellow-brown to black. At harvest and in storage, the pustules dry and break down leaving circular to oval pits which are filled with brownish spore balls. Sometimes these pits can enlarge to form cankers in the tuber, in which a dry sunken rot may develop.

Description for photo 13

This is an image of the initial symptoms of powdery scab which is caused by the fungus Spongospora subterranea. You can see the purplish brown sunken lesions on the surface of the yellow potato. The lesions appear to go slightly deeper than the surface of the potato and are relatively small in size.

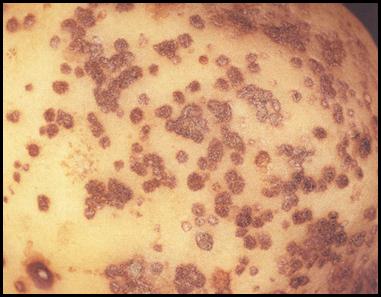

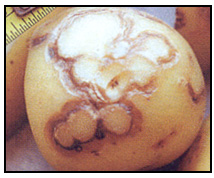

Description for photo 14

This image shows the development of brown raised pustules, a symptom of powdery scab. The yellow potato in this image is covered in small reddish-brown spots, due to some of the pustules close proximity to on another they appear patch-like.

Description for photo 15

This is an image of enlarged pustules on a yellow potato. They appear brown and are raised significantly over the surface of the potato. The pustules seem to resonate in close proximity to one another and look enlarged to about 6 mm in size.

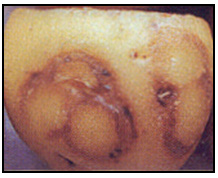

Description for photo 16

This is an image of a potato with pustules that have burst and released spores. The pustules span approximately 60% of the visible potato. There are circular to oval pits that are filled with greyish, brownish spore balls in the place of the pustules. The edges of the pits appear rough and flaky.

Description for photo 17

This is an image of ruptured pustules on a brown potato. You can see the dry, flaky edges of where the pustules ruptured leaving in its place a slightly darkened pit of dry sunken rot. The pits are located closely together, and at times, forming one large patch of sunken pustules.

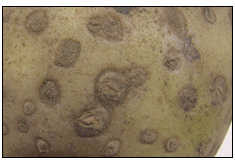

5b: Common Scab

Common Scab, Surface Scab, and Russet Scab are all caused by common soil bacterium, Streptomyces spp. which may survive in the soil for long periods of time even in the absence of potatoes. The bacteria are generally spread in the same manner as Powdery Scab by planting infected tubers, moving or spreading contaminated soil or manure. The strains which cause scab infections produce a toxin which results in the formation of lesions on the tuber. Initial symptoms are small reddish-brown lesions around the lenticels of young tubers. In ideal conditions, the lesions increase in size, turn dark and form circular scabbed areas that are either isolated or in large corky masses. They may be superficial spots or greatly roughened blotches. The scab will appear as both smooth and rough, or may be cracked.

Description for photo 18

This is an image of two initial reddish brown lesions on a yellow potato. In the image the lesions are magnified in size. This makes the detail of the lesion more evident i.e. you can see a crack emerging from the centre of the lesions (in the case of the second lesion multiple cracks).

Description for photo 19

This image is of a yellow potato with severe scab. The potato's surface is 40% covered in small reddish-brown scabs that are found in close proximity to one another. The scabs appear flaky with pieces easily coming off.

Description for photo 20

This is an image of a brown potato with deep lesions (Pitted Scab). The lesions penetrate deep into the potato. The potato looks dry and rough with the edges of the lesion peeling and curling inwards. The lesions take up a great portion of the potato leaving minimal surface unaffected.

Description for photo 21

This is an image of raised corky, brown tissue on the surface of potato. It appears to emerge from the white potato's surface and looks dry with a bark-like texture.

Description for photo 22

This is an image of net-like scab lesions. The scab lesions cover approximately 50% of the visible potato. The brownish, dry scabs are closely placed for the most part giving the appearance of one big scab. The scab appears rough in texture.

Description for photo 23

This is an image of severe lesions on a yellow potato's surface. It appears red and raised with a rough texture.

Description for photo 24

This is an image of an extensive scab on tubers. You can see many brown potatoes with deep lesions affecting a good portion of each potato - at least 40%. The deep lesions appear to penetrate well into the potatoes.

5c: Scoring

Scoring:

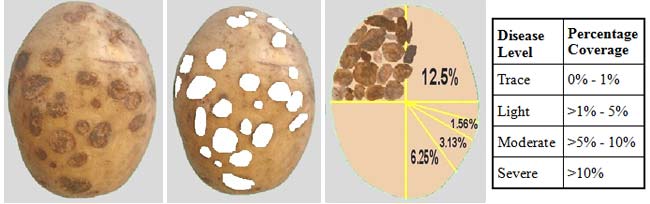

For tuber grade tolerance, Scab is treated in the same manner and under the same tolerance as Rhizoctonia. The total amounts are combined under the same tolerance when both diseases are present. In general, all Scab is treated equally for domestic and some export destinations depending on their current import requirements. In order to approximate the percentage coverage of the tuber, the surface can be divided into three dimensional quadrants as illustrated below (25); each half of the tuber represents 50% of the surface area. The size of quadrant the lesions would occupy if all lesions were pooled into a single area of the tuber will help to determine the disease level for scoring purposes. Examples of trace to severe coverage, based on the exposed side of the tuber, are given below (26).

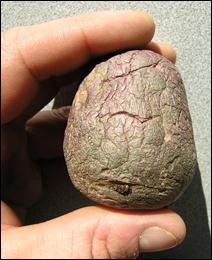

Description for photo 25

This image is made up of three pictures of the same brown potato. The first picture shows a potato with approximately 22 scabs. The second picture shows the same potato where the scabs have been digitally cut out of the picture leaving the rest of the potato in the picture. The third picture shows the cut out scabs from the picture superimposed on a silhouette of the potato. The scabs have all been grouped in the top left hand corner of the silhouette to show that they cover 12.5 % of the surface area.

| Disease Level | Percentage Coverage |

|---|---|

| Trace | 0% - 1% |

| Light | >1% - 5% |

| Moderate | >5% - 10% |

| Severe | >10% |

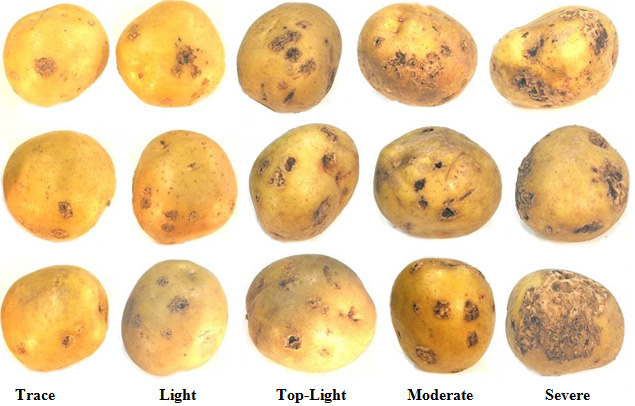

Description for photo 26

This image shows 15 tubers arranged in five columns of three potatoes each. The potatoes in the first column all show trace amounts of scab; the second column shows potatoes with light scab; the third column shows potatoes with the top end of light scab; the fourth column shows potatoes with moderate scab, the scabs are in a higher frequency and in closer proximity to one another. The fifth and final column shows potatoes with severe scab, the scabs cover a large portion of each of the potatoes.

Appendix 6

6a: Rhizoctonia

Causal Agent:

Rhizoctonia solani (Black scurf; Rhizoctonia) is a common seed and soil borne fungus which survives as black resting structures called sclerotia. In the soil, the fungus can also survive as fungal threads, called mycelia on organic debris. Infections start when sclerotia in the soil or on seed tubers germinate, producing mycelia which colonize stems and roots near the seed piece. The pathogen enters tubers in storage by infecting lenticels, eyes, and skin. The fungus does not penetrate deeply into the tuber tissue. Pathogen growth on the exterior of the tuber can spread to other tubers in storage. The disease is favoured in tubers that are harvested late and stored under cool conditions. The fungus forms the characteristic black sclerotia (black scurf) on tuber surfaces before and after harvest. Planting seed potatoes infested with sclerotia increases the amount of Rhizoctonia inoculum in the soil. Rhizoctonia solani can survive in the soil for at least eight years.

Tuber Symptoms:

Rhizoctonia is identified by the presence of hard, black or dark brown sclerotia which adhere very tightly to the surface of the tubers, but do not penetrate the skin. Frequently referred to as "the dirt that will not wash off", sclerotia will vary in size from small specks to large masses up to 2.5 cm across. Infected seed may exhibit brown lesions on sprouts.

Description for 27

This image shows sclerotia, a symptom of Rhizoctonia, ranging from 0.1 to 2.5 cm on a yellow potato. You can see the sclerotia a black or dark brown, hard substance covering three quarters of the visible potato as well as in between its crevices.

Description for 28

This image shows a close up of "the dirt that will not wash off" i.e. sclerotia. The black/ dark brownish substance appears rough and hard on the yellow potato’s surface. The sclerotium has white specks on its surface. It appears to be firmly attached to the potato.

Description for 29

This is an image of fungal threads (mycelia) surrounding a lesion on a yellow potato. The lesion is magnified in the image so that it appears to be 1 inch wide, descending deep into the potato. In the area around the lesion there are white dry spots which seem elevated in comparison to the rest of the visible potato.

Description for 30

This image portrays sclerotia that can be picked off the tuber's surface. The image shows a close up of the sclerotia which appears like a brown, flakey scab that could be removed from the surface of the dry, yellow potato.

6b: Rhizoctonia - Scoring

Scoring:

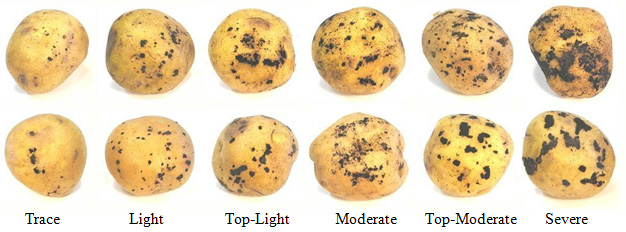

Rhizoctonia is rated in the same manner as scab and is scored either singly (if only one disease is present) or in combination with scab when both are present on the tubers being inspected. Refer to current tolerances as per Seeds Regulations Part II. In order to approximate the percentage coverage of the tuber, the surface can be divided into three dimensional quadrants where each half of the tuber represents 50% of the surface area (31). Both sides of the tuber are examined (32) and the disease level is estimated by the size of quadrant the sclerotia would occupy if pooled to a single area. Examples of trace to severe coverage are given below (33).

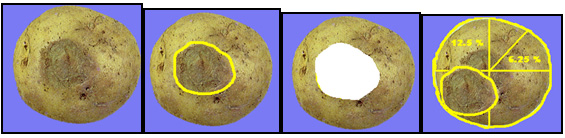

Description for 31

This image demonstrates the surface area percentages a defect can cover. The first tuber has a “50%” super imposed over it, in white, showing that the entire visible side of the tuber represents 50% of the total surface area.

The second tuber is divided with a black marker to show that ½ of the visible area of the potato represents "25%", 1/3 denotes "12.5%", 1/8 represents "6.25%", 1/16 of the potato signifies "3.13%", and 1/32 represents "1.57"”. Each marked area of the tuber has the corresponding percentage super imposed on it.

The third tuber is marked similarly to the second tuber but does not have the percentages marked on it.

| Disease Level | Percentage Coverage |

|---|---|

| Trace | 0% - 1% |

| Light | >1% - 5% |

| Moderate | >5% - 10% |

| Severe | >10% |

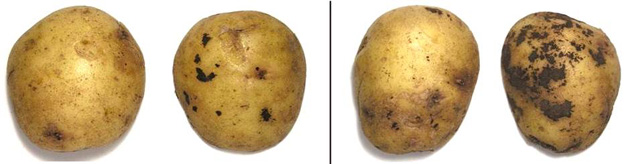

Description for 32

This image is divided into 2 parts: The first part has two pictures of the same tuber, one picture for each face of the potato. The potato in the first part is a yellow skinned potato with no sclerotia on the first side and the second side has very few sclerotia covering a small surface area.

The second part of the picture shows two images of the same potato but this potato has very few sclerotia on the first side and on the second side it has more sclerotia, covering approximately 50% of its face.

Description for 33

This image shows the gradient of sclerotia coverage from trace to severe. There are six tubers shown one image for each side in order they are: trace with 1% or less coverage of Rhizoctonia, light with >1% - 5% coverage of Rhizoctonia, top-light with 5% of Rhizoctonia, moderate with >5% - 10% coverage of Rhizoctonia, top -moderate with 10% coverage of Rhizoctonia, and severe with more than 10% coverage of Rhizoctonia.

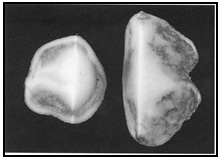

Appendix 7: Stem end discolouration

Stem end discolouration may be the result of various conditions, mainly heat necrosis, frost or drought. Treatments such as chemical vine killing may produce internal discolouration, usually resulting in a light brown, narrow ring in the flesh of transversely-cut tubers. General vascular discolouration may be caused by a number of biological factors including viral (e.g. net necrosis), fungal or bacterial. The symptoms are a slight discolouration of tissue below the stem-end, discolouration of the vascular ring appearing as slight netting, or in some cases a severe brown streaking through part of, or the entire vascular ring, sometimes extending nearly to the bud end of the tuber. Severe internal discolouration beyond the stem end (beyond 6-13 mm) should be scored under Malformed and Damage.

Frost injury or frost necrosis appears as a net necrosis of tuber tissue. Fine, dark brown to grey streaks or strands occur in the vascular ring or generally throughout the tuber flesh, giving the impression of a network. If the netting is due to frost, there are usually various stages of breakdown. Most frost injury should be scored under soft rot or wet breakdown, however mild stem end discolouration due to frost may be scored under stem-end discolouration.

Scoring:

It is not necessary to identify the specific cause of stem end discolouration, but all stem end discoloration is scoreable under its own tolerance in the Seeds Regulations Part II. The shoulder must be removed to ensure the reference for measurements begin at the stem end. Penetration between 6-13 mm at the stem end is scoreable. Cuts are made at the stem end of the tuber to determine the depth of penetration. If the discolouration extends beyond 13 mm, it is scored as an Internal Discolouration under Malformed and Damaged.

Description for 34

This image of two potatoes is an example of stem discolouration. The potatoes have a light brown skin with a cream-coloured center. Both have been cut to reveal their inner section below the skin and are shown from a top view in order to demonstrate the stem discolouration. With the discolouration in this image, at the center of the cut portion of each there is a dark/golden brown spot which then lightly radiates outwards to the rest of the cut area.

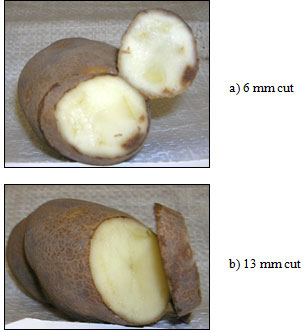

Description for 35

Image a) 6 mm cut

This image of a potato is an example of stem discolouration. The potato has a russeted skin with a cream-coloured center. Six millimeters have been sliced off the stem end and left attached beside the potato to reveal its inner section below, in order to demonstrate the stem discolouration.

Image b) 13 mm cut

This image of a potato is the same potato as the picture above. Thirteen millimeters have been sliced off of the stem end of the potato and placed beside the potato to reveal its inner section in order to demonstrate that the stem end discolouration does not penetrate to thirteen millimeters.

Appendix 8: Malformed and Damage

8a: Malformed

Malformed

Malformed tubers may take different forms. The tuber may have been exposed to adverse environmental conditions, or have a physiological defect, resulting in a knobby (36), pointed (37), curved (38), creased (39), or dumbbell shaped (40) tuber. In general, irregularities in soil moisture and nutrients are the common environmental factors responsible for malformed tubers. Growth cracks (41, 42) in the tuber may be caused by very rapid growth, usually when a rainy period follows a long dry spell. Growth cracks most often occur towards the bud end of the tuber and usually extend lengthwise. The cracks vary in size but usually heal over with no rot following the injury. Herbicide damage (43, 44) may result in malformed tubers, depending on the developmental stage of the plants at the time of exposure. Herbicides residues may be remaining in the soil, or drift from adjacent fields.

Scoring:

Tubers are to be scored as malformed when they are significantly different in shape from a typical tuber representative of the variety. Growth cracks are scoreable when they materially affect the bud end of the tuber (affect eyes and are not shallow) or extend more than 2/3 the length of the tuber in the aggregate.

Description for 36

This image of a potato demonstrates a potato that is malformed. The potato has yellow skin, with its centre being a spherical shape and, there are smaller knob-like bumps protruding from the centre. There are six knobs visible on the potato.

Description for 37

This image of a potato demonstrates a potato that is malformed. The right side of the potato in the image is a large round portion that becomes a curved, pointed end towards its left side.

Description for 38

This image of a potato demonstrates a potato that is malformed. The potato has dark-brown russeted skin, with a crease on the underside causing both of its ends to curve downwards.

Description for 39

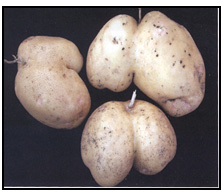

This image of potatoes demonstrates potatoes that are malformed. This image consists of three potatoes, each with a creamy-yellow skin. Each potato has two lobes attached together vertically, causing them to look similar to lungs. Between the two lumps there are creases.

Description for 40

This image of potatoes demonstrates potatoes that are malformed. This image consists of two potatoes with light-yellow skin, and are dumbbell-shaped – they have large ends and a thinner middle.

Description for 41

This image of a potato demonstrates a potato that is malformed. This potato has a light brown skin, and has a very large growth crack on its visible left side, which penetrates about one-half through the potato, with one side leaning backwards and the other forwards.

Description for 42

This image of a potato demonstrates a potato that is malformed. This potato has a light brown skin, and has a very large growth crack on its visible left side, which penetrates about one-half through the potato, with one side leaning backwards and the other forwards.

Description for 43

This image of a potato demonstrates a potato that is malformed. This potato has a light brown skin, and has a very large growth crack on its visible left side, which penetrates about one-half through the potato, with one side leaning backwards and the other forwards.

Description for 44

This image of a potato demonstrates a potato that has experienced malformation. This potato is an orange-brown colour, and demonstrates herbicide damage as the potato has many growth cracks giving it a blocky, shattered appearance.

8b: Insect Damage

Insect Damage:

Some of the more common insects which may feed on, or cause scoreable damage to tubers are listed below.

Wireworm (click beetle) larvae (45, 46, 47), Agriotes obscurus, A. lineatus and A. sputator have overlapping life cycles, so that tuber damage can occur at any stage during tuber development. Early season injury occurs when the tubers are small and the larva causes deep, funnel-shaped cavities which form as the tubers mature. Mid-season injury results in the formation of pits 6 to 12 mm deep and 1.5 to 3 mm in diameter, sometimes lined with discolored scar tissue. Late season injury consists of clean cut round holes and scar tissue is not prominent.

Flea beetle, Epitrix tuberis, may cause surface injury, internal injury or both. Surface injury consists of pimple-like eruptions or rough, winding galleries (trails) approximately 3 mm wide and of varying length. Internal injury consists of single, or groups of narrow, brown slivers or feeding tunnels that extend into the tuber between 5 to 20 mm. Cracks may occur where these tunnels come together.