Standard Inspection Process

On this page

- Acronyms

- Definitions

- 1.0 Purpose

- 2.0 Overview of the inspection

- 3.0 Step 1 – Prepare for the inspection

- 4.0 Step 2 – Conduct the inspection

- 4.1 conduct the opening meeting

- 4.2 Conduct the initial walk-through

- 4.3 Confirm the scope

- 4.4 Perform inspection tasks

- 4.5 Determine if immediate control action is required

- 4.6 Determine compliance

- 4.7 Categorize non-compliance

- 4.8 Determine timeframe for regulated party to complete corrective actions

- 4.9: Determine if response action is required

- 5.0 Step 3 – Communicate the inspection results

- 6.0 Step 4 – Conduct the follow-up inspection

- Appendix A: Recording inspection information in the Digital Service Delivery Platform (DSDP)

- References

Acronyms

- CFIA

- Canadian Food Inspection Agency

- CI

- Commodity Inspection

- CNC

- Categorization of Non-Compliance

- CRM

- Client Relationship Management (a Microsoft Dynamics software)

- DSDP

- Digital Service Delivery Platform

- ERA

- Establishment-based Risk Assessment

- iAIM

- integrated Agency Inspection Model

- IMS

- Issues Management System

- LSTS

- Laboratory Sample Tracking System

- OG

- Operational Guidance

- OGE

- Operational Guidance and Expertise

- PCI

- Preventive Control Inspection

- PCP

- Preventive Control Plan

- RDIMS

- Record Document and Information Management System

- SC

- Sample Collection

- SIP

- Standard Inspection Procedure

- SOP

- Standard Operating Procedure

- SME

- Subject Matter Expert

- SRM

- Specified Risk Material

- SRRP

- Standard Regulatory Response Process

Definitions

- Deviation

- A disparity between the regulated party's established preventive control plan (PCP) and the implementation of that preventive control plan

- Hazard

- A biological, chemical or physical property that may cause an unacceptable health risk.

- Non-compliance

- A contravention of the applicable Acts and/or Regulations

- Objective evidence

- Clear and factual information, derived from verification activities and the common inspection techniques, which support a non-compliance. This information is provided on the Inspection Report that will be submitted to the regulated party once the inspection is completed.

- Risk

- The product of the severity of the consequences of a hazard/concern and the likelihood of occurrence of these consequences.

1.0 Purpose

The Standard Inspection Process (SIP) is the common approach for conducting inspections across CFIA's 3 business lines (food, plant and animal health). The SIP follows the Integrated Agency Inspection Model (iAIM) in describing 4 standard inspection steps: preparing, conducting, communicating and following up on inspections.

2.0 Overview of the inspection

Canadian Food Inspection Agency (CFIA) inspectors conduct inspections to assess whether a regulated party is in compliance with regulatory requirements, and/or permission conditions (if applicable). There are 3 inspection task types: preventive control inspections, sample collection, and commodity inspections.

Preventive control inspection

The preventive control inspection task type is used for the evaluation of a regulated party's preventive controls to achieve compliance with regulatory requirements and/or permission conditions. This could include a regulated party's systems-based approach that focuses on prevention as a way to achieve compliance.

Sample collection

The sample collection task type is used for planned and as required samples which are submitted to the lab for analysis. This may include samples required for national sampling plans, verification against regulatory standards or requirements, complaints and investigations, surveys and surveillance.

Commodity inspection

The commodity inspection task type is used for the verification of a regulated party's product or thing against regulatory standards or requirements. It enables the analysis of a product or thing done by inspection staff, as compared to the sample collection inspection task type which require inspection staff to submit samples to laboratories for analysis.

Business line specific inspection procedures and other guidance can be found on Merlin:

- Food business line (accessible only on the Government of Canada network)

- Animal health business line (accessible only on the Government of Canada network)

- Plant business line (accessible only on the Government of Canada network)

The 3 inspection task types can be used alone, or in combination, in a single inspection case. For example, if during a preventive control inspection there is a need to verify compliance by using a different inspection task type: add a new inspection task using either commodity inspection task type or sample collection task type, and add the appropriate inspection task. Alternatively, if while conducting a preventive control inspection, a sample is collected for a national sampling plan (sample collection task type) a new sample collection plan case should be opened. Refer to the relevant business line guidance for the applicable inspection task types.

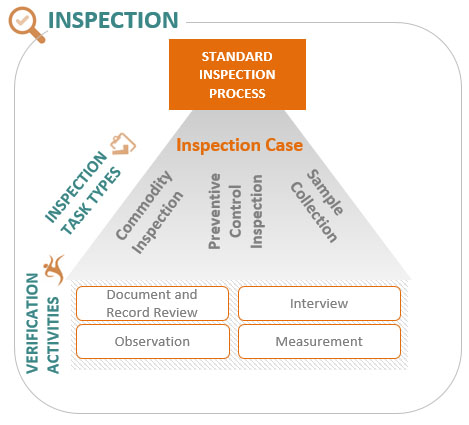

Figure 1. Descriptive text for the inspection process

The rectangle at the top of the illustration states Standard Inspection Process.

The triangle in the middle represents the inspection task types that are included within an inspection case.

The inspection task types are listed from the left to right in a vertical orientation: commodity inspection, preventive control inspection, sample collection.

The rectangle below the triangle represents the verification activities conducted as part of the inspection task types.

The 4 verification activities are listed in 2 columns from left to right: In the left column – Document and Record Review and Observation, and in the right column – Interview and Measurement.

Inspectors use common inspection techniques for all 3 inspection task types to gather information and verify compliance to the regulations or permission conditions, as applicable. This information is used to support compliance decisions and any actions taken by CFIA when non-compliances are identified.

Inspection information is entered and resides in the Digital Service Delivery Platform (DSDP). Procedures for the use of the DSDP to capture inspection data is found in Appendix A and on the DSDP Merlin page (accessible only on the Government of Canada network) in conjunction with the business line and commodity specific guidance.

The inspection process

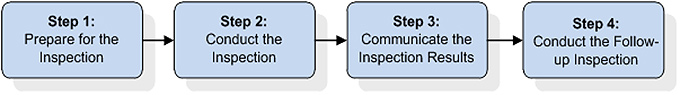

There are four steps for completing Preventive Control, Sample Collection and Commodity Inspections, as depicted in figure 2 below:

Figure 2: Descriptive text for the inspection process is represented by 4 boxes.

Arrows lead from one box to the next in the following order:

Step 1: Prepare for the inspection leads to

Step 2: Conduct the inspection leads to

Step 3: Communicate the inspection results leads to

Step 4: Conduct the follow-up inspection

At any point in the inspection, advice and/or guidance may be needed. To request advice and guidance:

- search for relevant operational guidance

- seek advice from the supervisor and the advisory community

- request advice or guidance from the appropriate Operational Guidance and Expertise (OGE) division, if advice or guidance is not available within the inspectorate or is still required

3.0 Step 1 – Prepare for the inspection

Objective:

- establish the purpose of the inspection

- familiarize with commodity, activities, hazards and controls, and the compliance history of the regulated party, where applicable

- determine the inspection tasks to be included as part of the identified scope

- identify areas for inspection emphasis

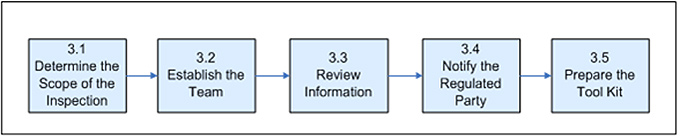

Preparing for an inspection consists of 5 parts, as represented in figure 3 below. However, note that the steps involved in the preparation of the inspection may not necessarily follow a linear process.

Figure 3. Preparing for an inspection consists of 5 parts represented by 5 boxes.

Arrows lead from one box to the next in the following order:

3.1 Determining the scope of the inspection

3.2 Establishing the team

3.3 Reviewing information

3.4 Notifying the regulated party

3.5 Preparing the tool kit

3.1 Determine the scope of the inspection

The Digital Service Delivery Platform (DSDP) is the central repository for planning inspections and recording inspection data. Each DSDP inspection case has a trigger and scope which includes one or more inspection tasks. The scope is determined by the trigger (reason) for the inspection. Refer to Section A.4.1 – Determine the scope of the inspection for more information.

Business line guidance indicates which DSDP triggers (reason for inspection) apply for specific programs. In the DSDP, there are 8 trigger options.

| Inspection trigger | Applied when |

|---|---|

| Preventive Control Inspection Plan | Conducting a preventive control inspection as per the national workplan |

| Sample Collection Plan | Collecting a sample to be submitted to a lab as per the national workplan |

| Commodity Inspection Plan | Conducting a commodity inspection as per the national workplan |

| Incident Response | Conducting an inspection in response to a suspect or realized risk |

| Domestic Permission | Conducting an inspection to support the issuance of a domestic permission |

| Export Permission | Conducting an inspection to support the issuance of an export certificate to a foreign country |

| Import Permission | Conducting an inspection to support the issuance of an import permission |

| ASD Verification | Conducting an inspection to verify that an alternate service provider meets CFIA requirements |

The scope of an inspection includes the following:

- One or more of the following inspection task types:

- Preventive Control Inspection

- Sample Collection

- Commodity Inspection

- One or more inspection tasks that are added to the inspection case in the DSDP

The inspection tasks may vary based on the inspection task type. A complete list of inspection tasks is available in the DSDP under Administration on the Site Map.

For information on accessing and creating an inspection case in the DSDP , refer to Section A.3 – DSDP inspection case information of Appendix A.

Planned and "as required" inspections

Planned inspections are conducted as part of the annual work plan. The scope is defined by the program direction and is generally pre-determined before the inspection case is assigned to the inspector.

"As required" inspections are those inspections conducted in response to an event (for example, complaints, referrals, a service request for an import, domestic or export permission or where required by law for interprovincial marketing purposes).

3.2 Establish the team

Inspections may be conducted individually or in teams. The team may include subject matter experts (SMEs) to perform specific functions or provide additional support. The SMEs do not need to be present for the entire inspection.

When inspections are conducted by an inspector accompanied by SMEs, the SMEs serve in an advisory capacity. Regardless of whether an individual or a team is needed, determine:

- the skills, knowledge, experience and qualifications required to conduct the inspection by considering:

- commodity, activities conducted by the regulated party, processes and/or treatment

- hazards, risk mitigation and control measures normally associated with the commodity/treatment/process

- inspection task type(s) assigned

- regulatory requirements and/or permission conditions

- the SMEs required, such as:

- biologists

- veterinarians

- process specialists

- inspectors with audit skills

- persons providing language interpretation

- the team size and composition based on needs while considering:

- the scope of the inspection

- size and complexity of the facility and its operations

- geographical location

- resources available

- roles, responsibilities and tasks for the team members and any SMEs

Consult with the supervisor to verify legal authorities related to conducting inspections with other government departments, prior to agreeing to conduct a joint inspection. In some cases, inspections may be conducted in conjunction with inspectors from other government (for example, provincial or federal) departments and from other CFIA programs.

3.3 Review information

Reviewing information is an important aspect of preparing for inspections. This includes information regarding the regulated party, the CFIA programs that the regulated party is associated with, their compliance history, applicable legislation and operational guidance and appropriate biosecurity measures to consider.

3.3.1 Regulated party/commodity information

Check to see if the regulated party has a party profile. If the party profile is not found in the DSDP, contact the regulated party and request that they enrol in My CFIA. If the regulated party does not enrol, follow the process outlined in the SOP Searching for Party Profiles and Establishments (accessible only on the Government of Canada network – RDIMS 10859888).

If the regulated party have previously been inspected by CFIA, review:

- information regarding the regulated party such as hours of operation, commodities/processes/activities, permissions, hazards and risk mitigation, and controls related to the activities examined as part of the scope of the inspection

- any changes to the regulated party information since the last inspection (for example, email addresses, emergency contact information)

- any correspondence (for example, emails, appeals, letters) related to the regulated party since the last inspection

For information on reviewing the regulated party's profile in the DSDP, refer to Section A.4.3 – Review information of Appendix A.

3.3.2 Compliance history

Review the regulated party's history including:

- past CFIA inspection results, actions on permissions and control and enforcement actions

- any previous non-compliances and the associated timeframe for completion of corrective action

- granted requests for an extension to the timeframe for completion of a corrective action

- analytical reports (for example, past laboratory results including all results deemed other than satisfactory)

- complaints and recalls related to the commodity (for example, CFIA's Issues Management System)

For information on reviewing the regulated party's compliance history in the DSDP, refer to Section A.4.3 – Review information of Appendix A.

3.3.3 Applicable requirements, documents

Review applicable regulatory requirements and/or permission conditions associated with the scope of the inspection and any additional relevant operational guidance and references.

For information on requesting additional advice in the DSDP, refer to SOP Requesting Advice for an Inspection Case (accessible only on the Government of Canada network, RDIMS – 9855738).

3.3.4 Applicable biosecurity measures

- Determine if the inspection location has biosecurity measures that need to be respected.

- Request biosecurity protocol(s) where commodity specific protocols exist.

- Review biosecurity measures applicable to the commodity and/or related activities to prepare accordingly. Ensure the flow of the inspection is conducted in a manner that does not introduce hazards and to reduce the potential of being a vector of pests, diseases and contaminants during the course of the inspection.

- Follow appropriate biosecurity measures for preparation, cleaning and sanitizing, for example, equipment and vehicles prior to arriving at the regulated party's premises.

- Review the Biosecurity for Inspection Activities OG (accessible only on the Government of Canada network – RDIMS 7500000), which provides horizontal guidance for the inspector to make decisions with respect to biosecurity measures.

- Review the Operation Procedure Sanitation and/or decontamination of mobile devices for routine operations.

For information on requesting additional advice in the DSDP, refer to SOP Requesting advice for an inspection case (accessible only on the Government of Canada network – RDIMS 9855738).

3.4 Notify the regulated party to schedule an inspection (when required)

CFIA inspectors have the authority to enter a regulated party's premises to perform inspections, announced or unannounced. The purpose of the inspection usually dictates if an announced or unannounced inspection is required. The inspectors are to use their judgement and consult with their supervisor to determine whether notification is required.

Inspectors may notify the regulated party to schedule an inspection to ensure that:

- appropriate staff are available on the inspection date

- the facility is in operation during a scheduled inspection

- specific processes and products are available to be inspected on the date of inspection

- CFIA is made aware of, for example, any changes to the regulated party's location, profile, responsible personnel and biosecurity measures prior to the inspection (NoteFootnote 1).

Notification can be provided verbally or in writing via an e-mail. The notification letter template (accessible only on the Government of Canada network, RDIMS – 11289579) can be used to assist in notifying the regulated party of a future inspection.

For information on completing the DSDP, refer to Section A.4.4 – Notify the regulated party of Appendix A.

3.5 Prepare the toolkit

- Review the list of equipment described in the Inspector toolkit (accessible only on the Government of Canada network, – RDIMS 11289973).

- Determine if any additional equipment is required based on the commodity and activities covered in the scope of the inspection.

For information on completing the DSDP, refer to Appendix A:

- Section A.3.4 – Recording time within the inspection case

- Section A.3.5 – Notifications using DSDP

- Section A.3.3 – Declining an inspection case

4.0 Step 2 – Conduct the inspection

Objective:

- to verify compliance to the regulatory requirements and/or permission conditions administered and/or enforced by the CFIA.

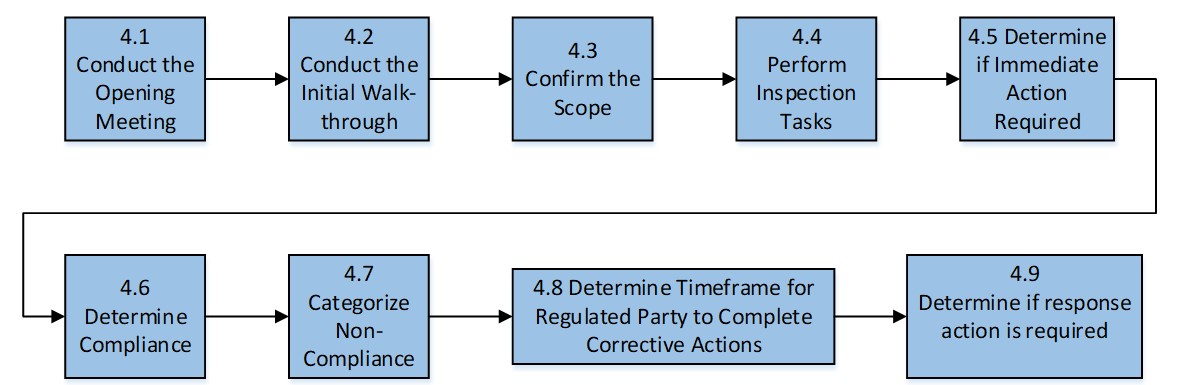

Conducting an inspection consists of the parts as represented in figure 4 below.

Figure 4. Conducting the inspection consists of 9 steps represented by 9 boxes.

Arrows lead from one box to the next in the following order:

4.1 Conducting the opening meeting

4.2 Conducting the initial walkthrough

4.3 Confirming the scope,

4.4 Performing inspection tasks,

4.5 Determining if immediate action is required

4.6 Determining compliance

4.7 Categorizing non-compliance

4.8 Determining the timeframes for the regulated party to complete corrective actions

4.9 Determine if response action is required

4.1 conduct the opening meeting

A preliminary step to conducting an inspection is to determine whether it is necessary to engage with the regulated party prior to initiating inspection activities. This level of engagement may be a simple greeting to notify the regulated party of the start of the inspection, or it may be a more formal opening meeting. A formal opening meeting is not always mandatory. For some inspections, (for example, surveying public lands for the presence of quarantine pests), engagement is not required.

When an opening meeting is required, the inspector will:

- communicate the legal authority, CFIA responsibilities, inspection scope, inspection process and resources required. to the regulated party, including those responsible for the activities being examined

- provide an opportunity for clarification and exchange of information

- confirm the official language of choice of the regulated party

The opening meeting may be formal or a basic discussion of inspection details.

During the opening meeting the inspector will:

- introduce all participants (CFIA, regulated party, SMEs and any other government personnel present), to clarify roles and responsibilities

- display CFIA designation card and/or badge

- provide the privacy notice statement by hard copy, or verbally prior to the inspection (Privacy Notice Statement, accessible only on the Government of Canada network – RDIMS 11606579)

- communicate the inspection scope, estimated duration, process to be used

- indicate that the regulated party will be advised of any changes to the scope during the course of the inspection

During the opening meeting the inspector may also (where applicable):

- identify the status of non-compliances from previous inspections, obtain the status of corrective measures, and confirm if any extensions to permanent corrective action implementation deadlines have been requested and granted

- request that key staff or resources required are identified and available to assist with the inspection

- confirm whether there are any changes to the regulated party's profile such as to the establishment, equipment, commodities or activities and note any revisions in the DSDP

- confirm the regulated party's biosecurity and health and safety standards (including applicable provincial legislation )

- advise that an end-of-day discussion may be conducted to provide information of the day's inspection results, including any non-compliance that were observed; that is, when inspections take more than 1 day to complete

- determine an approximate date, time and location for the closing meeting

Refer to Opening/closing meeting checklists (accessible only on the Government of Canada network – RDIMS 11289897) for an opening meeting checklist that can be printed and taken out on inspection.

For information on completing the fields relating to the opening meeting in the DSDP, refer to Section A.5.1 – Conduct the opening meeting of Appendix A.

4.2 Conduct the initial walk-through

An initial walk-through is not mandatory for all inspections. The inspector uses their judgement to determine if an initial walk-through is necessary.

If an initial walk-through (interior/exterior) is conducted then:

- observe any new commodities, operations, equipment, establishment extensions and practices

- identify aspects within the preliminary scope that should be either emphasized or targeted for more intensive inspection and areas that should be added to the scope of the inspection (for example, add preventive control sub-element tasks; commodity inspection tasks; or sample collection inspection tasks)

- ensure the permissions are aligned with the activities taking place

- ensure that the flow of the inspection does not introduce hazards and respects biosecurity principles applicable to the commodity and/or related activities

- verify, where applicable, that interim measures are still effective for outstanding non-compliances where the timeframe for completion of corrective actions has not yet passed

For information on completing the fields relating to the initial walk-through in the DSDP, refer to Section A.5.2 – Conduct the initial walk-through of Appendix A.

4.3 Confirm the scope

When confirming the scope:

- determine if the preliminary scope remains the same or if an amendment is required

- identify aspects within the preliminary scope that should be either emphasized or targeted for more intensive inspection and areas that should be added to the scope of the inspection (for example, add preventive control, sample collection, or commodity inspection tasks)

- record the justification for the change to the scope where applicable

- communicate any changes to the scope to the regulated party as soon as possible

Respect the preliminary scope where possible.

Potential reasons to amend (change, expand or reduce) the inspection scope include:

- identified potential food safety concern or potential plant or animal health issue

- changes in activity (for example, regulated party has begun or stopped exporting)

- recalls or complaints

- non-compliance with contributing factors linked to another sub-element outside the initial scope

- outstanding non-compliances within sub-elements not in the current inspection scope where interim measures are not effective.

If outstanding non-compliances have been discovered in the initial walk-through, verify that interim measures are still effective. If the interim measures are no longer effective, and the applicable tasks are not already within the initial inspection scope, then expand the scope and perform the activities related to the outstanding non-compliances.

For information on confirming or adjusting the inspection scope in the DSDP, refer to Section A.5.3 – Confirm the scope of Appendix A.

4.4 Perform inspection tasks

Performing inspection tasks allows an inspector to verify a regulated party's compliance to regulatory requirements and/or permission conditions. DSDP inspection cases will normally include one or more inspection tasks of the three inspection task types (preventive control inspection, commodity inspection or sample collection).

The 3 inspection task types can be used alone, or in combination, in a single inspection case. For example, if during a preventive control inspection there is a need to verify compliance by using a different inspection task type, add the appropriate commodity inspection or sample collection task to the existing inspection case. Alternatively, if while conducting a preventive control inspection, a sample is collected for a national sampling plan (planned sample collection) a separate inspection case should be used. Refer to the relevant business line guidance for the applicable inspection task types.

For information on the fields associated to all task types in the DSDP, refer to Section A.5.4.1 – Inspection verification activities for preventive control inspections, sample collection and commodity inspections of Appendix A.

4.4.1 Preventive control inspection

The preventive control inspection task type is used for the evaluation of a regulated party's preventive controls to regulatory requirements and/or permission conditions. This could include a regulated party's systems-based approach that focuses on prevention as a way for a regulated party to achieve compliance.

This inspection type evaluates the regulated party's preventive controls as applicable to the regulated party's operation including regulatory requirements and/or permission conditions for animal and plant health, food safety and labelling, product quality, and composition.

Preventive control inspections may be required to evaluate systems based programs prior to approval, or to maintain the permission or status in specific programs.

The inspector uses the outcomes, verification activities and performance criteria related to each preventive control inspection sub-element to evaluate compliance of a regulated party's preventive controls against the applicable regulatory requirements and/or permission conditions. This evaluation could include the assessment of a regulated party's written program, documents and records, observations at the facility, measurements and interviews with employees. Each preventive control inspection sub-element lists the outcome, verification activities and performance criteria that will be required to perform the inspection.

4.4.2 Sample collection

The sample collection task type is used for planned and as required samples which are submitted to the lab for analysis.

Samples may be required for national sampling plans, verification against regulatory standards or requirements, complaints and investigations, surveys or surveillance. Examples include sample collections for product identity, assessment for soil or pests, evaluation for toxins or disease.

Business line guidance provides procedures for the notification and submission of samples to the laboratories. The Laboratory Sample Tracking System (LSTS) is the main tool used by the CFIA to track and compile the information pertaining to laboratory samples. Business line operational guidance describes the manner in which sampling information is collected, analyzed and reported.

For information on capturing notes relating to taking samples in the DSDP, refer to Section A.5.4.1 – Inspection verification activities for preventive control inspections, sample collection and commodity inspections of Appendix A.

4.4.3 Commodity inspection

The commodity inspection task type is used for the verification of a regulated party's product or thing against regulatory requirements and/or permission conditions. It enables the analysis of a product or thing done by inspection staff, as compared to the sample collection task type which require inspection staff to submit samples to laboratories for analysis.

Commodity inspections can consist of a wide range of inspection activities that are conducted by the inspector on the commodity including, for example, label verification, crop inspection, specified risk material (SRM) inspection.

The inspector evaluates commodities based on applicable regulatory requirements and/or permission conditions. Business line operational guidance describes the manner in which commodity information is evaluated and reported.

For information on capturing notes relating to document and record reviews in the DSDP, refer to Section A.5.4.1 – Inspection verification activities for preventive control inspections, sample collection and commodity inspections of Appendix A.

4.4.4 Inspection verification activities for preventive control inspections, sample collection and commodity inspections

Inspectors use a combination of inspection verification activities to assess compliance to regulatory requirements and/or permission conditions for all 3 inspection task types (preventive control inspection, sample collection, and commodity inspection), including – where applicable:

- document and record review

- observation

- interview

- measurement

4.4.4.1 Document and record review

The purpose of examining documentation is to:

- target areas, product or processes to be inspected (for example, areas of higher risk)

- verify if the procedures are complete, implemented accordingly and are effective

- verify that regulatory requirements and/or permission conditions pertaining to documents and records are being met

Examples include processing records, complaint records, training records, sanitation records sample and testing results, certificates, receiving records, PCP, permission documents.

If applicable, inspectors should review documentation and records using the following guidelines:

- select a representative cross-section of the records to identify and observe any deviations and corrective actions taken

- note any inconsistencies (for example, gaps, anomalies)

For information on capturing notes relating to document and record reviews in the DSDP, refer to Section A.5.4.1 – Inspection verification activities for preventive control inspections, sample collection and commodity inspections of Appendix A.

4.4.4.2 Observation

Observation is not limited to visual assessment alone; it may also include sensory factors such as using hearing, touch and smell.

The purpose of observations is to gather information to evaluate whether:

- the commodity meets regulatory requirements and/or permission conditions (for example, no contamination observed, no unacceptable odours)

- the program is implemented as described and is effective

- the conditions of the premises and locality (for example, weather, environmental factors) impacts food safety, animal or plant health or compliance to regulations

- the conditions and functioning of the equipment impacts food safety, animal or plant health or compliance with regulatory requirements and/or permission conditions

- the employees are conducting their work activities, as per the established procedures

For information on capturing notes relating to observations in the DSDP, refer to Section A.5.4.1 – Inspection verification activities for preventive control inspections, sample collection and commodity inspections of Appendix A.

4.4.4.3 Interview

The purpose of the interview is to confirm that the employees:

- understand the procedures that they are to follow to produce safe and compliant commodities, and have put these procedures into practice

- know when and how to take corrective action if an issue or deviation arises; including taking immediately control of affected or potentially affected product(s)

- keep accurate and complete records

- have appropriate training to conduct their assigned tasks

For information on capturing notes relating to observations in the DSDP, refer to Section A.5.4.1 – Inspection verification activities for preventive control inspections, sample collection and commodity inspections of Appendix A.

4.4.4.4 Measurement

Measurements taken during the course of an inspection, support compliance decisions and allow the completion of assigned inspection tasks activities. Measurement includes activities such as taking temperature, humidity, moisture content or presence of soil. This section also allows for specific descriptors to be documented such as tattoo identification, lot identification and breed, or example.

For information on capturing notes relating to measurements in the DSDP, refer to Section A.5.4.1 – Inspection verification activities for preventive control inspections, sample collection and commodity inspections of Appendix A.

4.5 Determine if immediate control action is required

At any time when conducting an inspection, where it is determined that there is a potential for human, animal or plant health, or the environment or economy/trade to be severely impacted, inspectors may need to take control action by conducting the following:

- communicate and discuss the issue with their supervisor (if necessary) to determine if immediate action is required

- communicate and discuss the issue with the regulated party contact to see if further action is required and ensure immediate action is taken to control the affected commodity:

- determine if the entire affected and potentially affected commodity is under control (for example, initiation of a health or safety investigation)

- initiate control action (for example, seizure, detain product, stop production, recall, etc.) if the whole commodity is not effectively controlled

- use the Standard regulatory response process (SRRP) and business line specific guidance, which outline the control action available

For information on capturing notes relating to control actions in the DSDP, refer to Section A.5.2 – Conduct the initial walk-through Actions of Appendix A.

4.6 Determine compliance

During this step, inspectors interpret and analyze the information collected during the inspection to determine compliance with regulatory requirements and/or permission conditions. Inspectors take into account all inspection information gathered and make determinations and decisions regarding compliance.

A non-compliance is a contravention of a regulatory requirement or failure to meet permission conditions.

A non-regulatory non-compliance is a failure to meet permission conditions, which are not stipulated in legislation. The inspector identifies during data entry whether the non-compliance is regulatory or non-regulatory.

- Non-regulatory non-compliances include requirements under voluntary program that are not cited in regulations; any other kind of individual permission; or any license condition not set out in law.

- A non-regulatory non-compliance should not be selected within the DSDP unless stated in program or commodity-specific guidance. Failure to meet with a best practices manual is not a form of non-compliance.

If no non-compliance is observed during the inspection proceed to Section 5.0 Step 3 – Communicate the inspection results.

If non-compliance is observed, proceed to Section 4.7 Categorize non-compliance.

For information on capturing the non-compliance and objective evidence in the DSDP, refer to Section A.5.5 – Determine Compliance of Appendix A.

4.7 Categorize non-compliance

The categorization of non-compliance (CNC) assesses the potential consequences of a non-compliance and the likelihood of occurrence. The purpose of categorizing a non-compliance is to inform:

- timeframes for regulated party to complete permanent corrective actions

- timeframes for CFIA follow-up inspections

- adjustment of level of CFIA oversight

- program design/re-design

The process of CNC is organized into 4 steps (Sections 4.7.1 to 4.7.4) which seek to answer questions raised intuitively when assessing the level of impact that may result from a non-compliance.

The category of non-compliance is based on the impacts of the individual non-compliance, not on the compliance history or intent of the regulated party. Compliance history and intent will be taken into account as part of the regulatory response process, if required. Refer to the SRRP.

The Categorization of Non-Compliance Process document (accessible only on the Government of Canada network – RDIMS 11292219) outlines the process for CNC.

4.7.1 Identify the non-compliance type and sub-type

Identify the type and sub-type of non-compliance based on the information collected during the inspection.

Select all applicable types and sub-types that reflect the impact caused by the non-compliance. see below for a list of non-compliance types.

| Type | Sub-type | Characteristics |

|---|---|---|

| Health (human, animal, plant) |

Biological | Any pathogen, pest or vector of a pathogen or pest that poses a danger to human, animal or plant health or the environment (for example, bacteria, viruses, parasites, prions, insects) |

| Health (human, animal, plant) |

Chemical | A chemical substance that is not normally found in a commodity or that exceeds allowable levels in a commodity and poses a danger to human, animal or plant health or the environment (for example, veterinary drugs, contaminants, pesticides, toxins) |

| Health (human, animal, plant) |

Physical | Any foreign material that is not normally found in or on a commodity or that poses a danger to human, animal or plant health or the environment |

| Health (human, animal, plant) |

Allergen | The presence of undeclared or improperly declared allergens |

| Health (human, animal, plant) |

Nutritional | Incorrect nutritional composition in a commodity |

| Health (human, animal, plant) |

Animal Welfare | Conditions of the environment or situations/practices that may cause avoidable injury, avoidable suffering or death of animals (for example, overcrowding, restricted space, improper ventilation) |

| Environmental | Other | Any issues that may create an environmental concern (for example, contamination from plants with novel traits, invasive alien species) |

| Economic | Consumer protection, Fraud, Misrepresentation, Risk to industry sector, Other | Issues resulting in unfair economic gain for the regulated party; economic loss to consumers, competitors or industry sector because use of unfair or deceptive practices |

| Trade | Risk to export eligibility, Other | Issues affecting or having the potential to affect domestic or international trade or relations |

| Other | Other | No effect on humans, plants, animals, the environment, the economy or trade |

4.7.2 Determine the severity of consequence(s)

Determine the severity of the consequence of the non-compliance if the consequences were to occur.

The 3 levels of severity of consequences are defined as:

Low: exposure to the hazard/concern is not likely to cause any adverse consequences for humans, plants, animals, the environment, the economy or trade

Medium: exposure to the hazard/concern could result in temporary or non-critical consequences to humans, plants, animals or the environment or have a moderate effect on the economy or trade

High: exposure to the hazard/concern could cause permanent disability or death for humans, plants, animals, or serious effects on the environment, the economy or trade

If there is insufficient information to determine severity, use the Guide for determining the severity of consequences of non-compliance (accessible only on the Government of Canada network – RDIMS 11289853) to help determine the level of severity (low, medium or high). If the guide does not provide enough information to help in the determination of the severity, then the severity is "high" until demonstrated otherwiseFootnote 2.

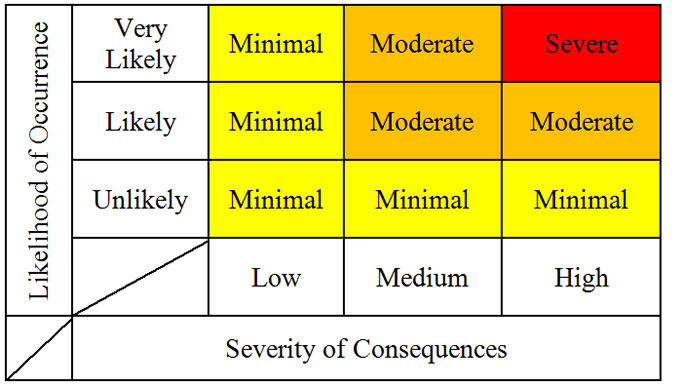

The severity of consequences is represented on the horizontal-axis in Figure 5 used in section 4.7.4.

4.7.3 Determine the likelihood of occurrence

Determine the likelihood of occurrence of the consequences of the non-compliance, based on the controls of the regulated party over the hazard or concern.

The 3 levels of likelihood are defined as:

Very Likely: There are little or no control(s) in place, the controls are not effective or there is high potential for exposure to the hazard or concern

Likely: There are some control and/or mitigation measures in place and there may be gaps, inconsistency, or some potential exposure to the hazard or concern

Unlikely: The controls are in place and effective, mitigation addresses the issue and there is minimal potential exposure to the hazard or concern

To determine the level of likelihood, consider the inspection results related to control measures.

Review control measures that reduce, mitigate or increase the likelihood of occurrence. Consider the regulated party's controls from initial inputs to end use.

Determine the likelihood of occurrence (very likely, likely or unlikely). Below are some considerations when making the determination:

- if the likelihood of occurrence cannot be determined due to high uncertainty, then very likely is selected until additional information can be obtained

- identify whether there are any controls

- determine effectiveness of controls (for example, are they working and doing their job)?

- review the controls in place for the preventive control inspection sub-element(s) where the non-compliance was found

- review the controls in place for the preventive control inspection sub-element(s) other than where the non-compliance was found

- review control measures at any other point in the process that reduces, mitigates or increases the likelihood of occurrence

- does the non-compliance affect other control measures (other controls will be rendered ineffective)

- do other controls or factors exist that may eliminate or minimize the likelihood of occurrence of the hazard (for example, the commodity is subject to additional processing before packaging, the animal is vaccinated prior to movement)

- do conditions exist specific to the commodity or host that would cause the likelihood of exposure to the hazard to decrease or increase (for example, mitigating factor or aggravating factor like a commodity that supports the growth of the biological hazard)

- determine effectiveness of controls considering the initial level of contamination

Depending on the inspection type, different information is available to help determine likelihood of occurrence:

- preventive controls and performance criteria can be considered for a preventive control inspection as well as for any commodity or sample collection inspection task types created under a preventive control inspection

- preventive controls and performance criteria are not considered if a commodity or sample collection inspection task type is done outside of a preventive control inspection

If the consequence of the non-compliance has already occurred, the probability of occurrence is very likely in all cases and for all types of inspection tasks.

The likelihood of occurrence is represented by the vertical-axis in the CNC Figure 5 used in section 4.7.4.

4.7.4 Categorize the non-compliance

Categorize the non-compliance based on its impacts using Figure 5 below:

Figure 5: CNC Matrix

The horizontal axis represents the severity of consequences and is divided into low, medium and high. The vertical axis represents the likelihood of occurrence and is divided into unlikely, likely and very likely.

A low severity of consequence results in minimal CNC for any likelihood of occurrence and the boxes are coloured yellow.

A medium severity of consequence results in minimal CNC for unlikely likelihood of occurrence and moderate CNC for likely and very likely likelihood of occurrence and the boxes are coloured orange.

A high severity of consequence results in minimal CNC for unlikely likelihood of occurrence represented by a yellow box, moderate CNC for likely likelihood of occurrence represented by an orange box, and severe CNC for very likely likelihood of occurrence represented by a red box.

The objective evidence should clearly support the categorization decision.

If a non-compliance has more than oneFootnote 3) non-compliance type or hazard or concern identified, repeat steps in sections 4.7.1 to 4.7.4 until the most severe category is identified and record the most severe category in the DSDP. In addition, identify whether a different requirement may be applicable to the other non-compliance type(s).

For information on capturing the categorization of non-compliance in the DSDP, refer to section A.5.5 – Determine compliance of appendix A.

4.8 Determine timeframe for regulated party to complete corrective actions

The regulated party is required to be in compliance at all times; however, it is recognized that they may need some time to take permanent corrective action when non-compliance occurs. In the meantime, effective interim measures must be taken to address any non-compliance.

The timeframe to complete corrective actions must reflect the severity of the impact of the non-compliance and take into consideration, when possible, the time required for the regulated party to address the root cause and permanently correct the non-compliance. Timeframes are assigned by the inspector based on Table 3. Where those timeframes are not applicable, more suitable guidelines may be found in business line or commodity specific guidance).

For example, a non-compliance that requires immediate action should be identified to the regulated party and must be addressed with an interim measure or permanent corrective action. If an interim measure is put in place, the inspector may allow up to 10 days for the regulated party to complete the permanent corrective action.

Note: For all non-compliances, the timeframe to complete corrective actions is calculated starting the day after the regulated party was notified by the inspector of the non-compliance.

| Non-compliance category | Timeframe for regulated party to complete corrective action (in calendar days) |

|---|---|

| Severe | Up to 10 days |

| Moderate | Up to 60 days |

| Minimal | Up to 180 days |

Where a corrective action was implemented prior to the closing meeting, the non-compliance record and a corrective action due date that aligns with the category of non-compliance must still be recorded in DSDP. A follow-up inspection will need to be conducted based on the timeframe for the category of non-compliance to ensure that permanent corrective action have been implemented.

For information on capturing the timeframe(s) to complete corrective actions and to whom the non-compliance was reported to in the DSDP, refer to section A.5.5 – Determine Non-Compliance and section A.5.6 – Entering Timeframe for Regulated Party to Complete Corrective Actions of Appendix A.

4.9 Determine if response action is required

In addition to determining the timeframe for corrective action, assess if control measures, enforcement actions or actions on a permission are warranted before the follow-up inspection.

Guidance on these assessments can be found in the Standard regulatory response process, the Enforcement and investigation file referral standard (EIFRS), and in business line policy or guidance.

For information on capturing the regulatory response in the DSDP, refer to Section A.5.5.2 – Capture regulatory response actions of Appendix A.

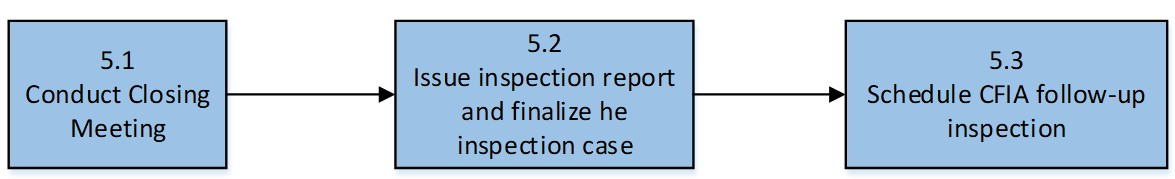

5.0 Step 3 – Communicate the inspection results

Objective:

- communicate the results of the inspection and any non-compliances observed

- provide an opportunity for discussion at the end of the inspection

- communicate the timeframes for the regulated party to complete permanent corrective actions

- evaluate requests for extension to timeframes for corrective action completion

- provide the written inspection report (when required)

Note: For inspections that span more than 1 day, a brief end-of-day discussion can be held to summarize the events of the day and to plan for the remainder of the inspection. The end of day discussions may precede a formal closing meeting in order to notify the regulated party of any non-compliance that have been identified prior to the completion of the inspection. The timeframes for the regulated party to complete corrective actions are calculated starting the day after the regulated party was notified by the inspector of the non-compliance.

Figure 6. There are 3 steps to communicating the inspection results represented by 3 boxes.

Arrows lead from one box to the next in the following order:

5.1 Conducting the closing meeting,

5.2 Issuing inspection report and finalizing the inspection case,

5.3 Schedule CFIA follow-up inspection

5.1 Conduct closing meeting

A closing meeting is held once the inspection and all inspection tasks are completed. The closing meeting may be formal or an informal discussion of inspection results. The purpose is to provide verbal feedback to the regulated party regarding the results of the inspection, and any non-compliance observed. In the situation where the inspector requires additional clarification (for example, with the supervisor at the CFIA office to review/validate inspection information) the closing meeting may be conducted up to a few days after the on-site inspection.

During the closing meeting, the inspector may, where applicable:

- discuss the overall results of the inspection

- discuss and clarify any actions or control measures taken by the regulated party or the inspector during the inspection

- provide a verbal presentation of all non-compliances identified

- communicate to the regulated party if further analysis and consultation are required to determine compliance

- provide the timeframes for completing corrective actions related to each non-compliance and explain that the follow-up inspection will assess if compliance has been re-established

- indicate that the inspection report will be provided as soon as possible (ideally within 5 working days from the notification of the non-compliances or at the closing meeting)

- respond to questions, concerns or requests for clarification expressed by the regulated party

- discuss any required next steps and expectations

Inspectors must notify their supervisor immediately if there is disagreement from the regulated party over the categorization of the non-compliance, any action taken by inspectors or the potential impact on the regulated party's operations or the commodity.

Refer to Opening/closing meeting checklists (accessible only on the Government of Canada network – RDIMS 11289897) for a Closing meeting checklist that can be printed and taken out on inspection.

For information on capturing notes relating to the closing meeting in the DSDP, refer to section A.6 – Communicate the inspection results of Appendix A.

5.2 Issue inspection report and finalize the inspection case

The inspection documentation presented to the regulated party is the DSDP inspection report. In certain situations, an inspection report may not be issued. Refer to program specific guidance for more information.

The purpose of the inspection report is to communicate to the regulated party:

- that an inspection was conducted

- which inspection tasks were completed

- all non-compliances found

- timeframe for completion of corrective action

The inspector returns to the office, completes the inspection report and submits it to their supervisor for review and approval, if applicable.

Once the report is approved by the supervisor, if applicable, the inspector sends it to the regulated party via the DSDP portal, as well as other means if requested (for example, email or fax). If the regulated party requests a meeting to discuss the inspection report, the inspector uses their judgement to decide if a phone call, or subsequent meeting is needed. The report should be signed by the inspector.

Review the CFIA fee schedule for fees that are linked to inspection tasks. Apply the fees according to the Operational procedure (OP/PO-175): Collection and invoicing of user fees for cost recoverable inspection activities and service requests (accessible only on the Government of Canada network – RDIMS 6159161).

Once the inspection report has been submitted to the regulated party and all required fields in the inspection case have been completed, the inspection case must be deactivated (closed) to prevent any further editing.

Reminder: Only details of the non-compliance and objective evidence is to appear on the inspection report. Recommendations and opinions are not appropriate.

For information on completing the remaining fields, generating an inspection report and saving this report in the DSDP, refer to Appendix A:

- section A.3.4 – Recording time within the inspection case

- section A.6 – Communicate the inspection results

5.3 Scheduling CFIA follow-up inspections

Follow-up inspections are conducted to verify that the permanent corrective actions are implemented and effective.

Timeframes for follow-up inspections are based on the regulated party's timeframe for corrective action, as per section 4.8. Use Table 4 below to guide scheduling of follow-up inspections.

| Non-compliance category | Timeframe (in calendar days) for CFIA follow-up inspection |

|---|---|

| Severe | Immediate or after the timeframe given to the regulated party |

| Moderate and minimal | After the timeframe given to the regulated party or at the next scheduled inspection |

The follow-up should be scheduled as soon as possible following the regulated party's Date for Completion of Corrective Action. However, there may be situations where the follow-up guidelines in Table 4 are not practical. For example, where seasonal operators are not in operation at the time of the follow-up inspection or do not have recently produced products for CFIA to verify compliance, follow-up inspections for these situations can be conducted at the start of the next season's operations, or at the next planned inspection. Additionally, timeframe for corrective action completion by the regulated party may be specified in guidelines found in business line or commodity specific guidance.

5.4 Review request for extension to timeframe for corrective action completion

In some situations, a regulated party may require more time to implement permanent corrective action than the timeframe originally allocated. For example, a regulated party may require major capital initiatives or additional time to satisfactorily implement corrective actions such as restoring building structures or purchasing new equipment. Where there is no impact on food/plant/animal health and the environment, timeframes to complete corrective action may be extended.

A written request can be made by the regulated party for an extension to the timeframe for completing corrective actions.

The following describes the information required and circumstances to be considered for the review and decision on whether or not an extension request should be granted.

5.4.1 Information required for assessing the request

Written requests for extensions must be submitted prior to the original established completion date.

The request includes:

- the rationale for requesting the change

- the non-compliances associated with the extension request, and a description of the interim measures

- a proposed new timeframe for the corrective action to be completed

- any additional documentation on the extenuating circumstances that supports the need for an extension

5.4.2 Granting and denying requests for an extension

An extension can be granted when:

- a written, valid request for an extension is submitted before the original established completion date which includes the required information as described in section 5.4.1

- human, animal, or plant health or the environment is not compromised, due to the extension and interim measures are effective

For information on capturing an extension in the DSDP, refer to section A.6.4 – Request for extension to timeframe to correct non-compliance of Appendix A.

Extension requests may be denied when criteria set out above and in section 5.4.1 are not met.

5.5 Formal review of inspection results

If the regulated party disagrees with the inspection results, they should contact the lead inspector named on the inspection report as a first step. If the concern continues to be unresolved, the regulated party can request a formal review by submitting the reason of the request in writing to the inspection supervisor prior to the Date for Completion of Corrective Action indicated on the inspection report and no later than 14 calendar days after the report issue date. It is important to note the regulated party must have interim measures in place to control any immediate risk, weather or not the regulated party requests a formal review of the inspection results. The submission for the request for review must include the DSDP inspection report and must clearly identify the section(s) of the report to be reviewed.

When the Inspection Supervisor receives the formal request for review from the regulated party, they should:

- confirm receipt of the request

- review the request with the lead inspector and inspection team

- support the lead inspector in seeking advice from local operations management and advisory staff as necessary

Following review with the Inspection Supervisor and other subject matter experts (Inspection Advisors, Inspection Team, Inspection Manager, etc.), the lead inspector decides whether to confirm or modify the inspection results.

If the lead inspector decides to modify the inspection results, they should:

- amend the inspection case by referring to section A.6.5 Amending a closed inspection

- add a note to the original non-compliance record to explain the modification (for example, that the inspection showed no non-compliance)

- if the Category of Non-compliance and Date for Completion of Corrective Action has been adjusted, update the non-compliance record accordingly, adjust the Due Date in the follow-up case and re-issue the inspection report

- if the corresponding follow-up case is no longer required, cancel it with the reason 'Cancelled – Inspection Decision Reversed' by referring to the DSDP SOP INS Update, Close and Cancel an Inspection Case (accessible only on the Government of Canada network – RDIMS 9852255)

The lead inspector documents the result of the review and the rationale for their decision using the Formal review record of decision template (accessible only on the Government of Canada network – RDIMS 20412890). The lead inspector uses the information from this document to complete the Formal review decision notification letter template (accessible only on the Government of Canada network – RDIMS 18868227).

The lead inspector uploads a copy of the Record of Decision, the Formal Review Decision Letter and the original Request for Formal Review in the Documents sub-grid of the Inspection case as document type "Decision Document".

The lead inspector should communicate the decision within 10 calendar days of receipt by sending a copy of the Formal Review Decision Letter to the regulated party with a copy to their supervisor. This will allow time for the regulated party to pursue the right to recourse, should it be required.

In situations where the disagreement can not be resolved, the regulated party should be directed to CFIA's Right to recourse information found in the Compliance and enforcement policy.

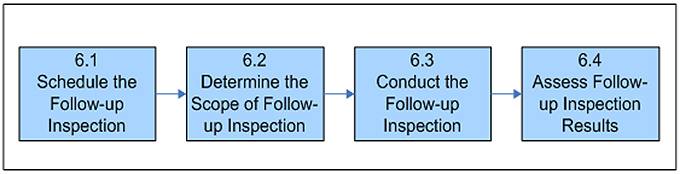

6.0 Step 4 – Conduct the follow-up inspection

Objective:

- Verify that non-compliance is corrected and a state of compliance is re-established.

Figure 7. Conducting the follow-up inspection consists of 4 steps represented by 4 boxes.

Arrows lead from one box to the next in the following order:

6.1 Scheduling the Follow-Up Inspection,

6.2 Determining the Scope of the Follow-Up Inspection,

6.3 Conducting the Follow-Up Inspection; and

6.4 Assessing the Follow-Up Inspection Results.

6.1 Schedule the follow-up inspection

Schedule the follow-up inspection, according to the guidance provided in section 5.3, Table 4, as appropriate. Prepare for the follow-up inspection following the guidance in Step 1 – Preparation.

6.2 Determine the scope of the follow-up inspection

To determine the scope of the follow-up inspection, the inspector:

- reviews the previous inspection report

- identifies the non-compliance(s) for which follow-up inspections are due

- selects the applicable inspection tasks which relate to the non-compliance(s)

For information on creating the follow-up inspection case in the DSDP, refer to section A.7.1 – Access the follow-up inspection case and capture inspection information of Appendix A.

6.3 Conduct the follow-up inspection

Conduct the follow-up inspection using the guidance in Step 2 – Conduct the inspection, and Step 3 – Communicate the inspection results to verify that non-compliance is corrected and a state of compliance is re-established and reoccurrence is prevented.

When conducting the follow-up inspection, perform the verification activities necessary to determine if the non-compliance(s) have been addressed.

Follow the procedures outlined below to determine the appropriate action to take for outstanding non-compliances. The procedures may vary based on the timeframe for corrective actions identified on the initial inspection report and the effectiveness of the corrective actions (permanent or interim).

For all outstanding non-compliances, discuss their status with the regulated party during the opening meeting. During the on-site inspection, verify that the interim measures that were taken by the regulated party are effective in addressing any non-compliance(s) where the timeframe for corrective actions has not yet passed.

For outstanding non-compliances associated to sub-elements or other inspection task not in the intended inspection scope, if:

- the interim measures are not effective:

- expand the scope by adding the appropriate sub-element(s) or other inspection task

- record the non-compliance in the inspection case

- take appropriate control or enforcement actions (refer to the Standard regulatory response process, if required)

- the interim measures are effective:

- do not add the sub-element or other inspection task to the scope

- proceed with the rest of the inspection

For outstanding non-compliances within sub-elements or other inspection tasks in the intended inspection scope, if:

- the timeframe for corrective actions has passed:

- verify that the non-compliances have been corrected

- the timeframe for corrective actions has not yet passed, and the interim measures are not effective:

- record the non-compliance in the inspection case

- re-categorize the non-compliance

- take appropriate control or enforcement actions (refer to the Standard regulatory response process, if required)

Note: At the time of follow-up, it may be necessary to re-categorize an outstanding non-compliance. The inspector will need to take into account circumstances at the time of the follow-up. The re-categorization of a non-compliance will result in a re-evaluation of the time frame for completion of corrective action.

For information on capturing notes and any non-compliance identified during a follow-up in the DSDP, refer to Section A.7.1 Assess the follow-up inspection case and capture inspection information of Appendix A.

6.4 Assess follow-up inspection results

Assess the results of the follow-up inspection.

Complete the inspection report if a state of compliance is re-established.. However, if a state of compliance is not re-established:

- notify your supervisor

- take the appropriate control or enforcement actions

- complete the inspection report

Appendix A: Recording inspection information in the Digital Service Delivery Platform (DSDP)

A.1 Purpose

The purpose of this appendix is to provide guidance to CFIA inspection staff on accessing, creating, assigning and completing inspection cases in the DSDP. This guidance is in relation to the guidance provided in the Standard inspection process for those sections where specific DSDP instructions are required.

Additional instructions on the use of DSDP are provided within the DSDP standard operating procedures (SOPs) (accessible only on the Government of Canada network) which are referenced in each section of this document, where applicable. These contain useful screenshots and information on navigating, creating various records and amending information. They can be found on the DSDP landing page on Merlin (accessible only on the Government of Canada network).

A.2 Overview of the DSDP

There are 5 distinct modules for CFIA's use of the DSDP:

- Enrollment

- Inspection

- Permissions

- Export

- E-billing

The DSDP is a tool that gives Agency staff the ability to issue export certificates and permissions (such as licences, permits, and registrations), capture inspection data, document compliance decisions, complete technical reviews, generate inspection reports, and assess and manage risk.

My CFIA is the web-based portal for industry to enroll and request permissions in the DSDP. For CFIA users, the DSDP can be accessed using the online Client Relationship Management (CRM) application.

Online system access for both training and production environments in the DSDP can be found on the Merlin DSDP web page (accessible only on the Government of Canada network). This site provides information related to training and support.

Roles and responsibilities of DSDP users

The administration of the DSDP and the creation and completion of inspection cases in the DSDP are assumed by different CFIA users, depending on their roles and responsibilities and the levels of access granted for these responsibilities. The following list provides a summary of responsibilities for different CFIA users:

Lead inspector

- creates and self-assigns a case triggered by an unplanned event

- documents/completes the inspection

- responsible for the final inspection decision

- responsible for notifying the supervisor of any reports ready to be approved

- generates and deliver the inspection report to the regulated party

- leads contact for communications with the regulated party (including any appeals)

- closes the inspection case

Inspection team members

- document/complete the inspection in collaboration with the lead inspector

Supervisor

- creates inspection cases, as required

- assigns the lead inspector and inspection team members within the inspection case

- approves inspection reports if required

DSDP administrator

- assists with business needs, such as DSDP access or connection problems

- completes any required system adjustments

- Reports inspection data

National Centre for Permissions Agents

- Receive and review permission applications

- Create permission inspection cases, when required

Data integrity and security

The DSDP inspection case contains data collected during the inspection that includes selections from reference data lists, entry of inspection specific data and inspector notes. This information entered in a Note in DSDP is not editable by the inspection case owner as soon as it is saved. However, all other information is editable until the case is deactivated. Records created in DSDP cannot be deleted so inspectors should be diligent before creating records. The system does have an audit function that can keep track of when changes are made and by whom. The completed inspection data and the inspection report have a security level of Protected B.

Entry of data into a single field by more than 1 user at the same time will result in the system overwriting existing data and only keeping the most recent entry. Due to this limitation, during team inspections, it is recommended that work is divided up among the team so that each inspector is responsible for entering data into specific assigned fields (for example, each inspector is assigned a different inspection task), or a single inspector is solely responsible for all data entry within the inspection case.

Should changes to inspection data be required after the inspection case is closed, a specific process must be followed for approval to make the amendment and to enable the system to track the change correctly. Refer to section A.6.5 below for more information.

A.3 DSDP inspection case information

A.3.1 Create and validate an inspection case

Inspection cases can be created several ways. For export service requests, the inspection cases are generated from the export case via the DSDP. For permission requests, the National Centre for Permissions may create an inspection case. For planned work, inspection cases may be uploaded in the DSDP at the start of the fiscal year. At other times, supervisors or inspectors may be required to create an inspection case. Regardless of where the inspection case is created, a validation step must occur to allow the inspection case to enter the inspection case queue and for inspection data to be populated within the case. Before an inspection case can be validated, there are several mandatory fields which must be completed. If these required fields have not been completed, the DSDP will alert the user with the appropriate fields that require attention in order for the validation to occur.

Refer to the SOP Creating an Inspection Request (accessible only on the Government of Canada network – RDIMS 9852034) for information on creating and validating an inspection case. A training module specific to creating inspection requests in the DSDP can be found on Merlin – DSDP learning and training (accessible only on the Government of Canada network).

DSDP Inspection triggers and establishing scope to validate the inspection case

Before an inspection case can be created in the DSDP, a fundamental field that is required for completion is the DSDP trigger field. These triggers are the reasons for the inspection, and include the following: preventive control inspection plan, sample collection plan, commodity inspection plan, incident response, domestic permission, export permission, import permission, and ASD Verification. Refer to the section 3.1 Determine the scope of the inspection for a complete description of triggers in the DSDP.

Only 1 inspection trigger can be selected for an inspection case. Therefore inspection activities conducted for different purposes (trigger), with different inspection tasks, should be captured in separate inspection cases. For example, if during the same visit, a preventive control inspection is completed and surveillance samples are required for a sample collection plan, the tasks relative to each of these inspection triggers should be captured in separate DSDP inspection cases. Refer to the DSDP case management practices for each business line for additional information.

DSDP data entry requirement to categorize commodity or thing inspected

Within the DSDP inspection record for sample collection and commodity inspection task types, under the field Commodity destined for field:

- 1) Product/thing was produced outside of Canada but imported for sale in Canada – select Import

- 2) Product/thing was produced in Canada and will be sold only within Canada – select Domestic

- 3) Product/thing is produced in Canada for the purpose of Export – select Export

- 4) Product/thing was produced in Canada but will be sold in Canada and may be Exported – select Domestic and Export

A.3.2 Work tasking and assigning an inspection case

Recently created and uploaded planned inspection cases can be found in the DSDP in the inspection case queue and will be identified with an "Active" status. Inspection cases should be 'Routed' to an inspector by a supervisor, or alternately, the inspector can 'Pick' an inspection case. These steps will ensure that:

- the work status of the case is updated to 'Assigned'

- the 'Worked by' column will be filled with the name of the user who has been assigned or who has chosen the inspection case. This function facilitates the quick visualization of all the inspection cases that have been assigned in the queue

The SOP Inspection work tasking (accessible only on the Government of Canada network – RDIMS 9881497) provides specific information on assigning inspection cases, locating inspection cases in a queue, transferring cases to another sub-district, self-assignment and adding/removing multiple inspectors. A training module specific to work tasking in the DSDP can be found on Merlin – DSDP learning and training (accessible only on the Government of Canada network).

A.3.3 Declining an inspection case

Inspection cases can be declined by an inspector and be subsequently re-assigned to another inspector by the supervisor. Declining an inspection case can only occur when the Work Status field indicates "Assigned" and a reason is entered into the system.

Refer to the SOP Inspection Work Tasking (accessible only on the Government of Canada network – RDIMS 9881497) and the SOP Preparing for an Inspection (accessible only on the Government of Canada network – RDIMS – 9852125) for more information on how to decline and re-assign an inspection case.

A.3.4 Recording time within the inspection case

The amount of straight timeFootnote 4 spent on an inspection by CFIA inspection staff must be recorded in the DSDP within the inspection case. Inspection time should be recorded for each inspection task, non-compliance, and for travel as follows:

Inspection tasks

Time spent completing an inspection task is limited to the time spent conducting the verification activities related to the task (as per the guidance in section 4.4 – Perform inspection tasks).

Time spent preparing, conducting the initial walk-through and opening/closing meetings is to be distributed evenly amongst the inspection tasks in scope. For example, if there are 6 inspection tasks and the inspector took 1 hour to prepare and 0.5 hours for the walk-through, then an additional 0.25 hours for each of the 6 inspection tasks would be recorded.

Each inspection team member (if more than 1 inspector is involved for the assigned inspection) is responsible for recording the amount of time spent to the nearest quarter hour on the inspection task.

Non-compliance record

Time spent completing a non-compliance record is limited to the moment a non-compliance is identified, the categorization of the non-compliance and the determination of the timeframes for completion of the corrective actions of any regulatory response actions in relation to that non-compliance.

Travel time

Record the total cumulative time to the nearest quarter hour spent on travelling to and from the inspection site by all inspectors/staff involved with the inspection case in the travel time spent field of the inspection details section of the inspection case. For example, if 2 inspectors are conducting an inspection together and it takes 1 hour to travel to the site and back, then record 2 hours in the travel time spent field.

If there are multiple sites to visit in a day, then only record travel time to a site in the inspection cases. The last site inspected must include travel back to the office in its associated inspection case. For example, an inspector travels 0.5 hours to site A, then travels 1 hour to site B, 1.5 hours to site C, followed by 2 hours to return to the office, then record 0.5 hours in the inspection case for Site A, 1 hour in the inspection case for Site B, and 3.5 hours in the inspection case for Site C.

The lead inspector is responsible for ensuring this information is entered in the travel time spent field.

Note: Time not directly related to conduct the inspection (general administration, break and lunch) is not to be tracked in the inspection case. Refer to SOP Conducting an inspection (accessible only on the Government of Canada network – RDIMS 9839405) for instructions on entering time entry records. Refer to specific business line guidance to confirm additional instructions for recording time.

A.3.5 Notifications using DSDP